Efficient and innovative: Openair-Plasma® surface treatment integrated inline in manufacturing processes

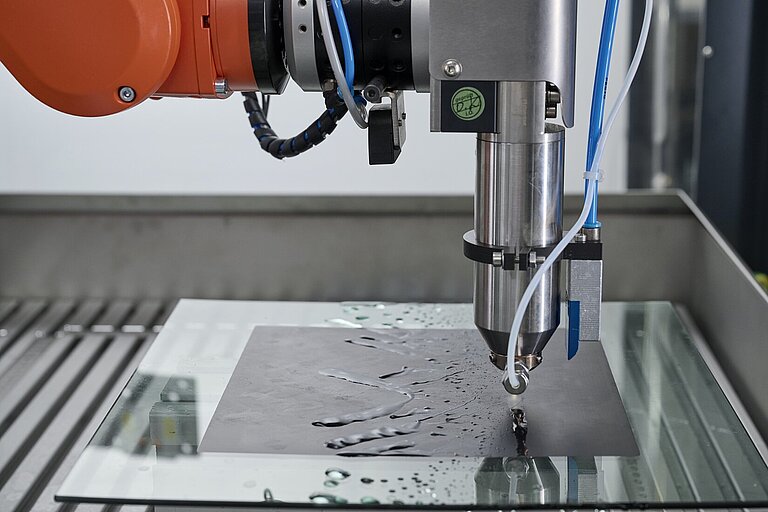

Typical application areas for use of atmospheric pressure plasma surface treatment technologies in further processing are adhesive bonding, composite bonding, printing, painting, coating, and two-component extrusion. Openair-Plasma® treatment is used in almost all industrial manufacturing processes—from packaging, printing, and the household appliance industry, to use in medical, electronics and textile engineering, in coil coating, and in the automobile, shipbuilding and aircraft industries.

In all these industrial application areas, materials like plastics, metals, glass, textiles, or films are bonded, printed, or painted. Here the combination of two dissimilar materials frequently presents a special challenge on the way to achieving new and customized material properties. Surface treatment with Openair-Plasma® can result in adhesion improvement, even for otherwise incompatible materials.