Plasma replaces primer

Without plasma surface treatment, many materials like polypropylene (PP), polyether ether ketone (PEEK) or polyoxymethylene (POM) cannot be bonded at all or bonded only poorly. High bonding strength and durable bonding of glass, metal, ceramic and plastics present special challenges for the manufacturing industry. Adhesion improvement via surface modification using Openair-Plasma® treatment with simultaneous ultrafine cleaning produces better adhesion capability and bonding strength on the surfaces to be joined.

Successful in countless application areas – better structural and composite bonding with plasma as adhesion promoter

There are a number of highly successful Openair-Plasma® applications for bonding plastics in the automobile industry alone.

Structural bonding

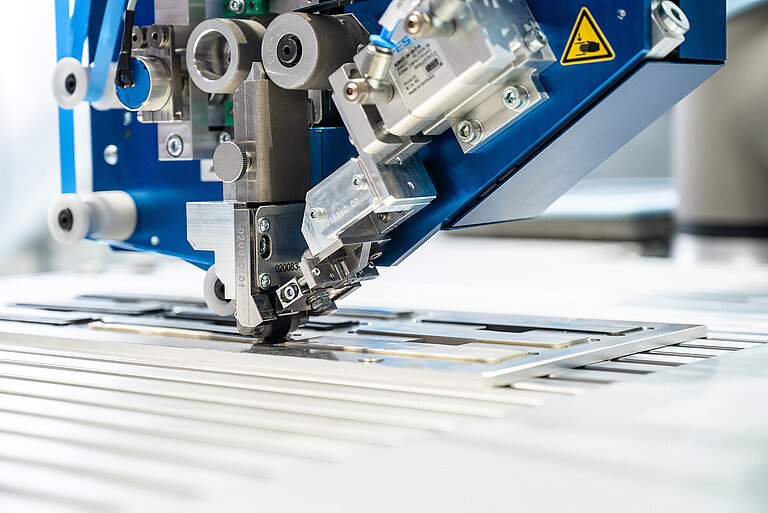

Plasma adhesive bonding technique for refrigerator truck superstructures in vehicle manufacturing

This application involves structural bonding of panel components. Openair-Plasma® pretreatment provides for improved adhesion capability on the surfaces to be joined and replaces all conventional cleaning or pretreatment processes.

Plasma adhesion improvement for modern automobile headlamps

For the first time, the use of Openair-Plasma® makes possible secure processing of the newly developed warm-melt 1-component PUR adhesives on nonpolar plastics (polypropylene). Openair-Plasma® surface treatment creates the required high surface tension on the materials to be bonded.

Bonding EPDM: Adhesion improvement for EPDM extrusion profiles

Previously, it was necessary to roughen EPDM profiles with rotating wire brushes during the process. Today Openair-Plasma® has established itself as the "state of the art" before application of flock adhesives or anti-friction coatings, especially in the automotive industry, because of the highly-effective and yet non-coating process.

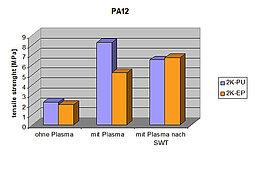

Age-resistant bonding of PA12 (polyamide)

2K-PU: Two-component polyurethane

2K-EP: Two-component epoxy resin

Bonding PA12 using polyurethane and epoxy adhesives. This graph shows a definite increase in tensile shear strength of the plastics treated with plasma. Even after a one-week saturated atmosphere test, the bond still exhibits high strength values.