Plasma Treatment: A New Way to Improve the Reliability and Life of LED Lights

LED technology nowadays plays an integral role in general lighting and in automotive engineering. LEDs have proved popular in general lighting due to their high energy efficiency, long life and adjustable light temperature. In the automotive sector, LED headlights are better at illuminating the traffic area, which increases road safety. The matrix LED front headlights used by major automotive manufacturers is a good example of this.

In automotive interiors it is the design freedom and different lighting effects which have helped LED technology become established. In addition to beam forming, increased resistance to environmental influences has been a major focus of development in LED lights. The aim is to increase the life of an LED and to ensure the core properties of color quality (chromaticity coordinates and color temperature) and efficiency over the product lifetime.

New manufacturing technologies address these developmental goals and offer opportunities for low-cost production.

The use of atmospheric plasma technology in LED production provides solutions to precisely these concerns:

- Lead frame cleaning (Openair-Plasma®) before the wire-bond process

- Improving adhesion of potting compounds to the molding compound (Openair-Plasma®)

- Applying an anti-stick layer on silicone mouldings (PlasmaPlus®)

Interesting success stories in this field

PlasmaPlus®—hydrophobic anti-adhesion coatings for encapsulated LED components

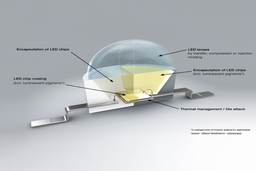

Large area displays composed of LED panels are being used for advertisement and announcements, for example in sport arenas. There can be up to millions of RGB-LEDs in one display. Each RGB-LED contains a blue, a green and a red emitting semiconductor chip. By steering the currents dedicated to each of these 3 chips, a large variety of colors can be achieved my mixing the emission spectra. Thermally stable silicones are used as encapsulants for the chips in the package.

However, the LED surface shows high tackiness caused by the soft silicone material, which may lead to problems during the manufacturing process of the LED as well as under operating conditions.

In the manufacturing process of display panels, the single LEDs are assembled to the board by a wave soldering process. Remanents of the LED stamping and bending process in the form of tin flakes accumulate in the soldering bath and frequently stick to the silicone surface of the LEDs and have a negative influence on the production yield. The tacki LED surface can also lead to problems during the pick and place process in the assembly of panels by sticking to each other or to the pick & place tool. This leads to lower production yield per time by many line stops. External influences during operation of the display, for example the collection of dust, accumulate over time to significant contaminations on the display.

By using the PlasmaPlus® -Technology, Plasmatreat has achieved the deposition of a thin, glas-like and anti-adhesive layer on the LED surface. This layer is highly effective versus any kind of contamination during manufacturing process and in later operation of the display, leading to increased production yield and longer lifetime of the display.

PlasmaPlus® protective coating prevents adhesive bleeding

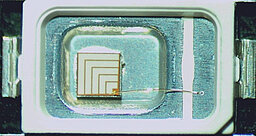

LED or semiconductor chip assembly processes typically use an electrically conductive, epoxy-based adhesive as a bonding agent. During thermal curing, low-viscosity components in the adhesive may flow out of the bond area and wet the surrounding surfaces, especially the electrical contacts for the wire bond pads. This phenomenon is known as 'bleeding'.

Adhesive bleeding weakens the connection between the contact wire and the wire bond pad. In the worst case the wire may lift, resulting in loss of electrical contact. Bleeding also has an adverse effect on the bond between the potting resin and the housing.

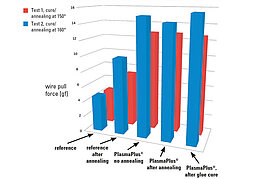

Working together with our partners, Plasmatreat has developed a special, ultra-thin nanocoating to address this problem. The PlasmaPlus® anti-bleeding coating prevents wetting of the contact surfaces and strengthens the wire connection, an added benefit which can be clearly demonstrated by wire-pull tests. The coating does not affect the bond between the adhesive and the lead frame. It is applied before chip bonding and remains extremely stable when stored under dry conditions.

Secure wire bonding thanks to Plasma cleaning (atmospheric or low-pressure)

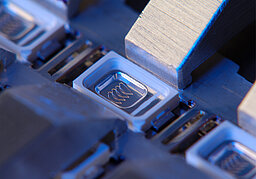

Clean contact surfaces on the lead frame are essential to ensure reliable contacting of the die with the lead frame. Even the slightest organic contamination reduces the quality of the aluminum-to-copper bonds. It will not be possible to generate enough heat to melt the wire, so the resulting bond will be a cold one.

Cleaning of the lead frames before wire-bonding, either by low-pressure plasma or by Openair-Plasma®, removes organic contaminants effectively and reliably.

The quality of ultrasonic friction welding is particularly improved by this cleaning process.