Our partner network

Plasmatreat has purposefully built up an innovative network of entrepreneurs, educational and research institutions, funding organizations, interest groups and associations in recent years. They all have something in common: the pursuit of new, good ideas for surface treatment. Our technology and innovation experts know their way around the various fields and use the combination of skills to bring new ideas to life again and again. At our events in the Plasmatreat Academy, we can draw on our partner network and invite them, for example, to joint networking events. Attending one of our events is definitely worthwhile, whether it is to gather ideas, to exchange ideas among like-minded people or to find support as well as a competent partner at your side for the current challenges or next innovation projects.

Our research at Stanford depends significantly on fruitful collaborations with industry partners, and I can say easily that Plasmatreat has been a close partner and collaborator in our efforts. We very much look forward to continuing our work together.

Successful industry partnerships

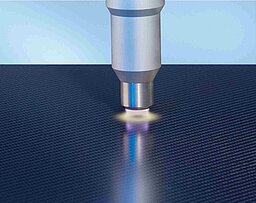

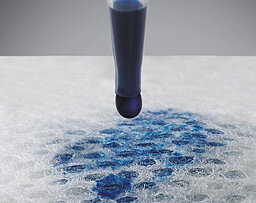

Working togehter for success with our partners in industry. Using our plasma technology in industry and offering the best solution is one of our guiding principles. To achieve this, we work hand in hand with our customers.

Our most inspiring R&D projects

Working together for success with our partners in science and conduct research with institutes and universities.