Durable and Corrosion-Resistant Sealing of Adhesive Bondlines

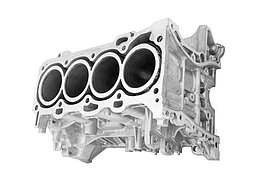

The demands made on modern automobiles are steadily rising. More and more electronics are required to satisfy high expectations regarding comfort and driving safety. Electronic circuits are also increasingly being integrated in decentralized sensors and actuators. The more complex the electronic circuit boards become, the greater the need is to reliably seal the components off from moisture and water (corrosion). Long-term sealing performance is equally important in powertrain applications. The task here is to prevent engine oil from escaping.

Topics on this page:

Plasma cleaning and selective coating Atmospheric plasma activation Plasma polymerization

Hot melt and silicone potting and encapsulation Reducing oil build-up Functional plasma coating

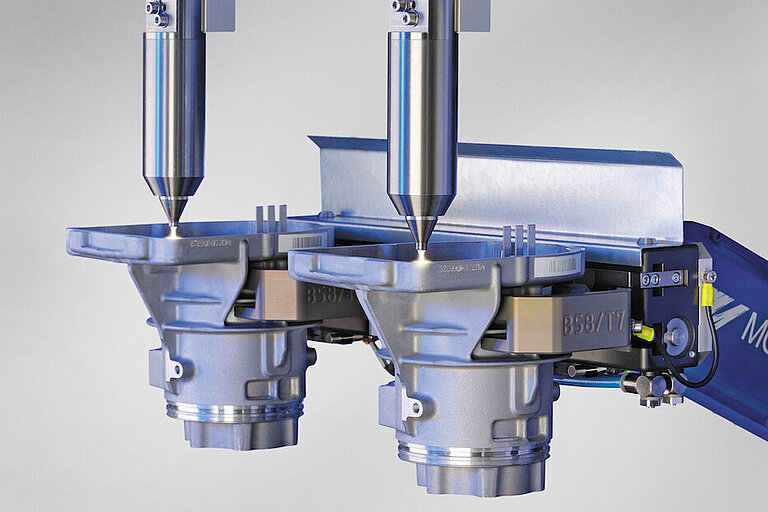

Plasma cleaning and selective coating for long-term sealing system performance

The quality of any seal depends especially on the cleanliness of the contact surfaces. In these critical zones, Openair-Plasma® cleaning assures targeted and effective pretreatment with high contour precision. For especially durable and corrosion-resistant sealing of adhesive bondlines, the PlasmaPlus® process developed by Plasmatreat is the ideal choice. In this type of plasma polymerization, a coating substance (precursor) is added to the plasma. The result is an exceptionally resistant corrosion protection seal.

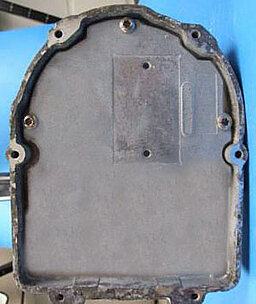

Processing Complex Electronic Housing Geometries Using the Low-Pressure Plasma Method

For electronic housings, particularly those with complex geometries, automating the selective scanning of the sealing surfaces can be challenging. In such cases, coating the housing using Aurora low-pressure plasma is a useful solution. Inside the low-pressure plasma chamber, a variety of parts can be cleaned and coated in one short cycle. This plasma deposited coating provides durable corrosion protection and prevents moisture infiltration, (especially for housings made of aluminum and magnesium alloys). No additional chemical treatment or painting is normally required.

In addition to anti-corrosion coatings, adhesion-promoting, hydrophobic and oleophobic coatings can be realized in low-pressure plasma. The functional coatings are used when steel and elastomer have to be bonded long-term or seals and filters are to be protected against permeation.

The introduction of Openair-Plasma® was a milestone in the development of our sensor production.

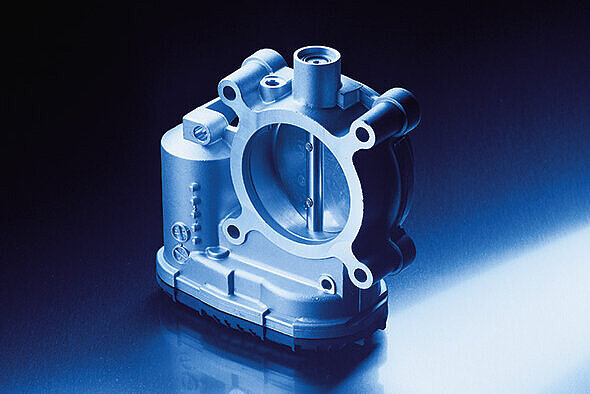

Atmospheric plasma activation: Sealing of electronic components

Engine control devices, anti-lock braking systems and on-board electronics are installed in the engine compartment and therefore constantly exposed to high temperature fluctuations and moisture. To protect the sensitive electronics, the printed circuit boards are encased in water- and dustproof housings. The sealing surfaces of these housings must be absolutely clean and free of grease and oil to ensure an impermeable seal.

Reliable protection of electronic components: sealing of plastic and aluminum housings

Openair-Plasma® enables automated and highly efficient cleaning and pretreatment of these surfaces prior to application of the sealing compounds and helps to achieve a high level of process reliability (plasma activation).

Plasmatreat has been approved as a plasma technology supplier by nearly all major manufacturers of engine electronics. Mature technology and worldwide service ensure trouble-free production processes.

Treatment of complex electronic housing geometries with the low-pressure plasma process

For electronic housings, particularly those with complex geometries, automating the selective scanning of the sealing surfaces can be challenging. In such cases, coating the housing using Aurora low-pressure plasma is a useful solution. Inside the low-pressure plasma chamber, a variety of parts can be cleaned and coated in one short cycle.

This plasma deposited coating provides durable corrosion protection and prevents moisture infiltration, (especially for housings made of aluminum and magnesium alloys). No additional chemical treatment or painting is normally required.

Interesting success stories in this field

Plasma polymerization guards against bondline corrosion

Corrosion creep along adhesive and sealant bondlines due to moisture penetration is a typical phenomenon in mating surfaces. Even good adhesion of the adhesive or sealant cannot completely rule out the risk of oxidative attack on the substrate itself.

Plasmatreat collaborated with the Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM) to develop the atmospheric plasma coating PlasmaPlus®. This is applied to the substrate at the same time as the plasma, thus effectively protecting the base material from bondline corrosion.

Even ultra-thin, nano-scale layers of this silica-organic coating achieve the desired long-term corrosion protection. This application has already been used successfully in industry for several years to manufacture electrohydraulic power steering systems (EHPS).

Compared with uncoated components, parts treated with plasma polymerization achieve significantly better resistance to environmental factors.

Hot melt and silicone potting and encapsulation for automotive sensors – protected by Openair® Plasma activation

Smart control systems interface with their surroundings by means of sensors. These sensitive electronic devices have to be protected against all environmental factors and especially against water (corrosion). To achieve this protection, the common practice in industry is to insulate the parts using hot melt or silicone potting and encapsulating compounds.

Through prior activation (plasma activation) of the electronic components and cable insulation sheaths, Openair-Plasma® ensures that the compounds will adhere securely and provide an absolutely tight seal around the device.

Reducing oil build-up in oil filters by oleophobic plasma coating

Oil filters media is generally constructed of a mixture of polyamide (nylon) and PET fibers. The filter needs to be replaced at regular intervals to avoid clogging of the filter, which could lead to engine damage. Clogged filters also result in poor engine performance and increased fuel consumption.

Oleophobic (or oil-resistant) surfaces in the filter matrix prolong the lifetime of the oil filter by reducing oil build-up in the filter. The Aurora low-pressure plasma technique is particularly well suited to depositing an oleophobic coating since it penetrates deep into crevices in the matrix of the filter media.

Functional plasma coating for sealing components

O-rings and other similar sealing components like shaft seals and retaining rings that are made of elastomers like NBR, FKM, FPM, EPDM, Viton, and silicone are used in many automotive applications.

Common uses for these parts include shock absorbers, engines, transmissions, brake systems, air conditioning units, and diesel injection pumps. For optimal performance, these elastomeric parts need to be coated to ensure they will not stick, and to make them resistant to oil and grease.

Fluorine-containing coating with low-pressure plasma

Using a low-pressure plasma process, gasses containing fluorine such as tetrafluoromethane (CF4) and sulfurhexafluoride (SF6) are used to coat components such as O-rings. Under normal conditions, these gases are exceptionally stable and do not react with other materials. However, when exposed to plasma, the fluorine bonds can be broken, creating highly reactive fluorine radicals that provide optimal surface properties. This allows the formation of barrier layers that protect the base material against permeation by fluids such as gasoline while preserving the elastic properties of the O-ring body. Further examples are PTFE and polysiloxane coatings that reduce friction and sticking.

FEATURES OF

plasma-coated elastomer parts

- Easy-to-assemble

- Reduced friction

- Better parts separation

- Abrasion resistance

- Improved chemical resistance

- Higher memory forces

Plasma pretreatment for high-temperature rubber-to-metal gaskets

High-temperature gaskets used to seal engines or equipment in the petrochemicals industry are often subjected to harsh conditions including high temperatures and pressures. For this reason, steel elastomer gaskets are often selected for these applications.

For production of these gaskets, Aurora plasma technology provides an environmentally friendly alternative to chemical adhesion promoters

To ensure that the steel and elastomer materials are securely, stably and durably bonded, the metallic part surfaces are coated in a low-pressure plasma chamber using a nano-scale adhesion promoting layer. This low-pressure plasma technology delivers effective, homogeneous coating and allows for high-volume processing.

Super-hydrophobic Non-stick coating of high-temperature (HT) gaskets

Another application for this technology is in non-stick coatings, particularly those using fluoropolymer chemistry. These coatings prevent the gasket from sticking to the component. Gaskets that have been coated in this way can still be easily removed from the component even after they have aged a great deal.

Our next PlasmaTalks and Events

Upcoming Exhibitions and Events

Get to know Plasma up close at our trade fairs and events!

FENSTERBAU FRONTALE

Hall 3, Booth 3-150

NürnbergMesse GmbH

Messezentrum

90471 Nürnberg

Germany