Efficient and automated pretreatment of paperboard packaging using plasma technology

Discover the impressive possibilities of our environmentally friendly and highly efficient plasma technology

Find out how our innovative Openair-Plasma® technology creates ideal adhesion properties for subsequent processing steps such as gluing, printing, foiling and varnishing.

Particular advantages of Openair-Plasma® technology in manufacturing carton packaging:

- Makes high processing speeds possible

- No open flames mean greater process safety.

- Robust, durable technology

- Simple process monitoring

- Cost effective

From cost efficiency and expanded material choices, to selective or full-surface treatment options, to reliable, structural bonding of materials - take the opportunity to learn more about the other benefits of our plasma technology in carton and folding carton production and converting.

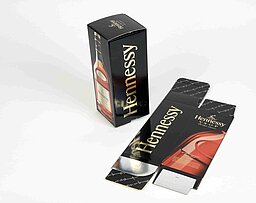

Modern folding cartons to meet the most demanding design and quality requirements: cost-effective and quick to produce with Openair-Plasma®

The trend in the packaging industry is toward continuously rising design and quality requirements. Manufacturers count more and more on the appeal of finishes like high-gloss printing, soft-touch coatings, or hologram printing to attract consumers. And display and window packaging often involve special combinations of materials.

These materials must be joined to each other cost effectively, at high speeds, and most of all reliably. This requires an especially robust, high-performance pretreatment process: Openair® Plasma.

When integrated inline, plasma activation creates ideal surface properties for subsequent process steps, such as gluing, printing or laminating.

Interesting success stories in this field

Gluing coated folding cartons: Openair-Plasma® surface treatment in pre-gluing machines

Today’s carton packaging is made from sheets that are printed, finished, cut, and folded in a folding machine and usually glued by the manufacturer (pre-gluing). This is accomplished on high-performance pre-gluing machines with speeds up to 600 m/min.

The glue that is used, cold glue, adheres without difficulty directly on bare paperboard material, but if that material already has a quality finish (such as a UV coating or laminated film), the places that will later be glued usually need to be roughened using an elaborate mechanical process (mechanical miller, sandpaper, brushes) in separate machinery. Otherwise, those spots must be masked before sealing.

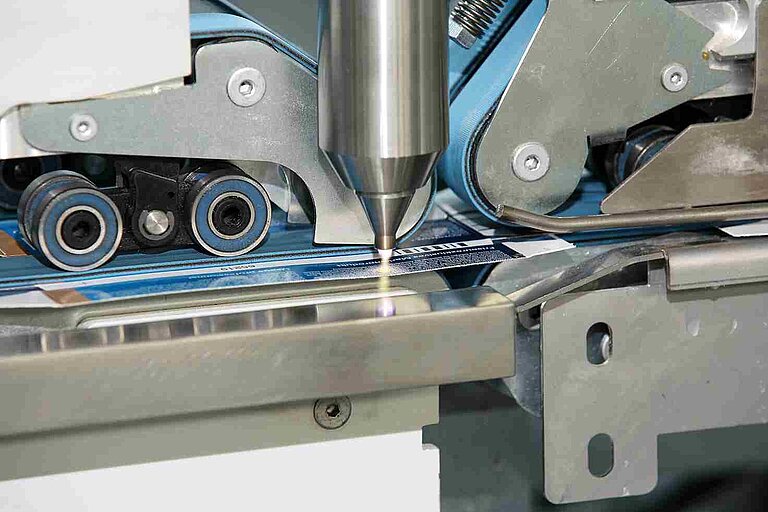

Integrating Openair-Plasma® technology significantly simplifies the process. Plasma jets are installed directly in high-speed pre-gluing machines where they pretreat the folding carton in the glue seam areas. The resulting increase in surface tension is enough to dramatically increase adhesion capacity; the cold glue that is generally used bonds regardless of the coating, varnish or surface sealing.

Gluing packaging directly in the set-up equipment: Openair-Plasma® makes quick bonding possible.

Right before printed and pre-folded packaging is filled, it is set up and opened, and – if necessary – also glued. Due to the fast processing speed and compact design of the equipment, the glue that is used at this stage must form a bond in the shortest possible time.

The increased surface tension that Openair-Plasma® creates results in fast and superior bonding regardless of the properties of the surface to be glued. So pretreatment with plasma makes it possible to process UV-coated or laminated carton packaging.

Simple, quick and efficient – optimal bonding of hot stamped foil on carton packaging

Hot foil stamping is often used for decorative finishing on packaging. These days, it’s difficult for cosmetics and even food to stand out from the pack without hot stamping on its secondary packaging or label. The range of applications in the graphic arts industry is practically limitless.

To bond hot stamped foil to non-polar polymer surfaces or glossy UV coatings or varnishes and ensure high quality, surface pretreatment is required. Openair-Plasma® offers an outstanding solution here too for the packaging industry.

Plasma pretreatment to activate surfaces can be integrated directly in the production process. Material blanks are precisely activated on those spots that will subsequently be hot stamped.