High degree of activation means new options in manufacturing and processing plastic packaging

The packaging industry can no longer get by without physical surface pretreatment. It’s become a necessary step in extruding plastic films and using non-polar materials such as polypropylene, polyethylene and recycled materials.

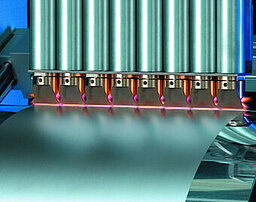

Openair-Plasma® is an especially effective tool in providing this pretreatment. Plasma treatment is a key surface modification technology that is critical to manufacturing cost-effective and environmentally responsible advanced composite materials.

Topics on this page:

Plasma treatment for plastic packaging Reliable ink bonding

Plasma treatment for plastic packaging is extremely effective:

- Openair-Plasma® surface modification technologies can achieve plastic activation at the highest level. It is not unusual to reach surface tensions of more than 72 mN/m.

- Extremely long-lasting plasma activation increases storage life and facilitates subsequent processing up to 12 months later.

- New material composites are only possible using targeted surface functionalization with Openair-Plasma®.

- Openair-Plasma® treatment ensures targeted, exclusively single-sided surface pretreatment of plastic films.

Surface tension is the key to the bonding of synthetic laminated, varnish coated and solid plastic boxes.

Reliable ink bonding for expiration dates on tubular bag packaging

The biggest segment in the plastics packaging industry is certainly tubular bag packaging. From chocolate bars to medical secondary packaging, products are packaged using this technology. Secure marking of expiration or sell-by dates is essential.

Openair-Plasma® treats packaging at just the right spot for optimum ink bonding, to ensure that printing ink applied by the ink jet process will adhere securely. Modifying the surface tension effectively increases the wettability of the film packaging. In particular, quick-drying UV-curing inks can be reliably used with this pretreatment.

The better alternative: plasma pretreatment for broad packaging film webs

Plastic film is typically produced using blown film and film stretching processes. The corona process is often used to pretreat these films for printing and finishing processes, but this poses its own problems. The corona process achieves only limited surface tension that declines significantly after just a few weeks in storage. And as an outcome of the process, even minor contamination on pretreatment rollers can result in punctures on the reverse side of the material.

Plasmatreat has developed two especially reliable techniques for pretreating packaging film with typical web widths of 2.2 to 8 meters:

- Plasmatreat Glow Plasma achieves especially cost-effective, durable surface activation at the highest level. Surface tensions of up to 64 mN/m are reached in the process.

- Openair-Plasma® treatment with patented sheet die technology ensures absolutely single-sided pretreatment of plastic packaging films. Punctures on the reverse side are impossible; and the adhesion values show exceptional long-term stability. Openair® plasma’s advantages are especially evident at high processing speeds and when recycled materials are used.

Openair-Plasma® for thermoformed film for food – better bonding of printing inks at high processing speeds

High quality printed images are a necessity, especially on food packaging. Ink can’t bleed into the product, however, and that ink must bond securely to the packaging. Printed cups, such as for yoghurt or margarine, must be stacked together for transport before they are filled but ink transfers from one printed exterior to the interior of the next cup must be avoided at all cost.

Pretreatment with Openair-Plasma® can safely prevent this undesired effect. Thanks to plasma activation, bonding of printing inks to the food packaging is substantially improved. Inks will not rub off. The speed of subsequent flat or rotary screen printing can also be significantly increased.

Secure ink bonding on plastic caps thanks to plasma pretreatment

Caps on plastic bottles must be absolutely airtight but they should also be easy to open. To ensure these qualities, silicone-modified compounds are used for these caps.

These materials have low surface tension, however, so printing on them (especially with solvent-free food-safe inks) can only be accomplished after plasma treatment. For that reason, Openair-Plasma® has been used by leading manufacturers for years to increase surface tension on bottle caps.

The plasma jets are integrated directly into modern pad printing machines that operate at high speeds.

Longer shelf life: PlasmaPlus® nano-coating improves barrier properties of plastic packaging

The shelf life of soft drinks in polyethylene terephthalate (PET) bottles is greatly limited by the barrier properties of PET, in particular when it is under pressure, such as from carbonation. If the packaging leaks CO2 or if oxygen from outside can penetrate it, that will change the flavor and quality of the soft drink.

Plasmatreat has developed a nano-coating for the soft drink industry that is transparent like glass and yet flexible and shock and friction resistant. This nano-coating significantly reduces diffusion and extends the shelf life of the soft drink. The coating is applied using the innovative and cost-effective PlasmaPlus® process and can be applied on both the inside and outside of the packaging.

This same improved barrier property provides a solution for the pharmaceuticals industry as well when this nano-coating is applied to plastic packaging to extend the shelf life of medicines and ensure their long-term active ingredient properties.

Our next PlasmaTalks and Events

Upcoming Exhibitions and Events

Get to know Plasma up close at our trade fairs and events!

PlastIndia Delhi

Hall, Booth H4GM-D17

Bharat Mandapam

New Delhi India

SEMICON Korea 2026

Booth P409, The Platz Hall

COEX

513, Yeongdeung-daero, Gangnam-gu

Seoul, South Korea

JEC World

Hall 5, Booth G65

Paris Nord Villepinte Exhibition Centre

ZAC Paris Nord 2

93420 Villepinte

France