Openair-Plasma® for Textile Manufacturing Yarn Finishing

In fiber and yarn technology, the focus is on the first step of the textile production chain. Modern textiles demand durable, stable colorfastness while simultaneously reducing the use of solvents.

Durable, stable colorfastness: High-speed plasma treatment in yarn finishing

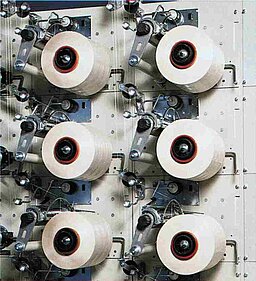

Plasmatreat has developed and patented an innovative plasma technology for the pre-treatment and finishing of new polymers, filament and staple fibers. The wettability of the fibers and yarns is measurably increased, allowing even solvent-free dyes to bond well and durably. High-speed Openair-Plasma® jets can keep pace with the demands of new high-performance technologies in advanced filament spinning equipment that can attain speeds of up to 1000 m/min.

Special advantages of Openair-Plasma® technology in treating yarns:

- Dry physical surface modification

- Durable hydrophilic yarn finishing

- Fully automatic, reliably monitored production process, with up to 8 yarns per plasma jet (yarn jet)

- Extensive know-how and test systems for treatment of textiles and yarn

Removing conditioners and desizing with Openair-Plasma® – extremely efficient and environmentally responsible

High-performance manufacturing processes in the textile industry would be unthinkable without sizing. Sized fibers are silkier, more resistant, and have the best finish for withstanding the mechanical stresses of weaving and tufting, for example.

But this same sizing proves to be very detrimental to subsequent processing of the threads or fibers. Its hydrophobic quality makes wettability more difficult during the dyeing process and thus interferes with color bonding on the yarns and fibers.

During embedding in resin to make fiber-reinforced composites, high-quality bonding of the fiber to the resin is impossible without efficient removal of the size.

With its combination of physical, chemical and thermal effects, Openair-Plasma® technology provides the optimal process to efficiently remove sizing and conditioner from the yarn. And it does this without physically damaging the fibers and most importantly, in an environmentally responsible way.

A “Hint of Glass” - innovative flame-retardant finish for textile polymer fibers, with PlasmaPlus®

Plasma polymerization with PlasmaPlus® is an extremely effective process to apply functional nano-layers on the surface of yarns. These layers can be adjusted to be hydrophilic or hydrophobic, depending on the precursors used. One relevant application in functionalization of textiles is fire-retardant coating.

The French institute CREPIM (Centre de Recherche et d’Etude sur les Procédés d’Ignifugation des Matériaux) has done extensive studies investigating the flame-retardant effect on textiles achieved by plasma polymerization. Even the application of very thin glass-like layers dramatically reduces the flammability of polymer fibers, due to the inorganic nature of the coating.

Plasma singeing of staple fibers in carpet manufacturing – can be precisely controlled and carefully measured for a soft, pleasant hand

Especially in the American carpet industry, competition focuses on staple fibers versus filament yarns. The look and hand of staple fibers is far superior to that of filament yarns, however, there is a problem with showing dirt and lint buildup. These are both caused by the fact that natural staple fibers are composed of individual segments, which require surface treatment in the form of finishing.

With traditional processes, such as gassing with a gas flame, remaining tiny filaments are mechanically singed or burned in order to remove them. But that often results in a hard feel to the final product. Singeing with Openair-Plasma® is an effective alternative to flame singeing that retains the quality of the fibers since the plasma jets can be carefully controlled and precisely administered in the process.

Our next PlasmaTalks and Events

Upcoming Exhibitions and Events

Get to know Plasma up close at our trade fairs and events!

FENSTERBAU FRONTALE

Hall 3, Booth 3-150

NürnbergMesse GmbH

Messezentrum

90471 Nürnberg

Germany