PFW10 and PFW20 – specific plasma systems for different requirements

The plasma jets directed onto the material are used to generate and spread the plasma (cold plasma is generated). The plasma is generated inside the jet by a high voltage between a stator and a rotor and is blown out through the jet head using working gas.

With its patented jet systems, Plasmatreat has developed extremely robust, highly effective tools for industrial surface treatment. Both single jets and rotating plasma systems are available as plasma sources.

Single jets have a relatively small outlet angle and are therefore better suited for the treatment of narrow profiles. Rotating plasma systems, which distribute the pretreatment effect evenly onto over the larger work width as a result of the rotation principle, are better suited for wider processing surfaces.

Pretreatment with the Openair-Plasma®

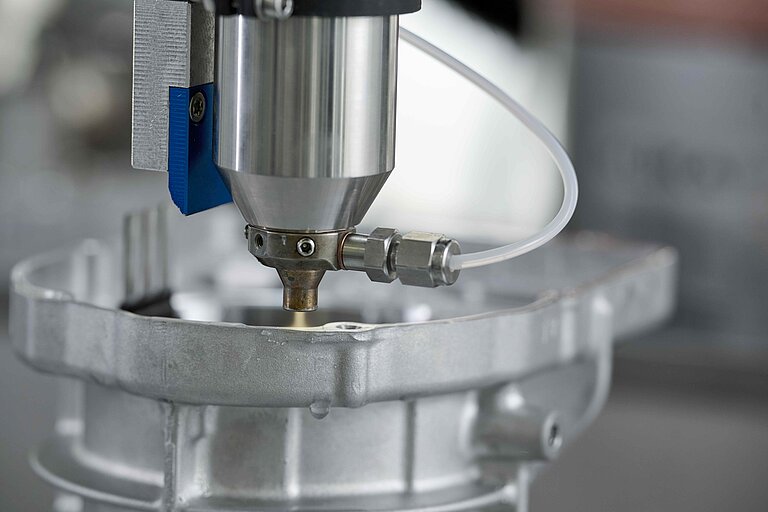

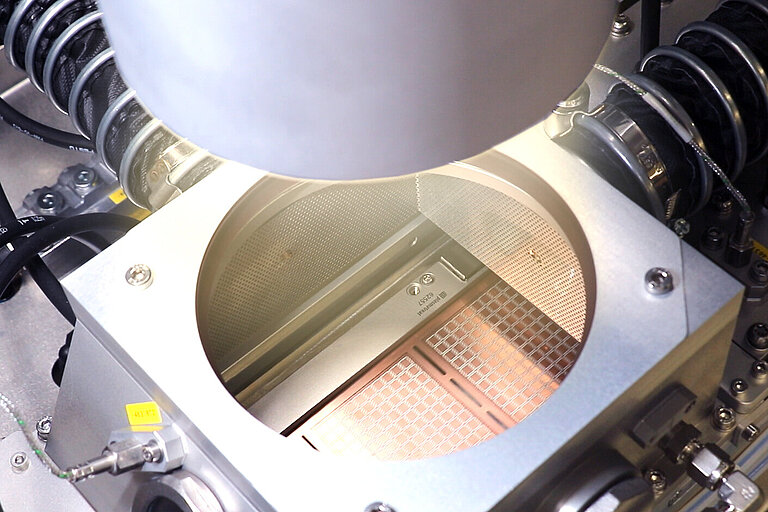

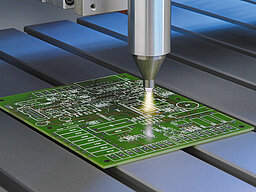

Pretreatment with the Openair-Plasma® jet PFW10 is done with very high contour accuracy and is potential-free (no transfer of voltage to the material). This type of plasma jet is mainly used when parts are to be plasma-treated with high process speed, high energy, or selectively when only a certain part of a work piece (e. g. a bonding groove) is to be treated. The Openair-Plasma® jets PFW10 and PFW20 are also well suited for the potential-free plasma treatment of very sensitive components, such as circuit boards.

Optimal tuning of the pretreatment process to the specific properties of the work piece

Openair-Plasma® jets are adjusted to the process specifically for the application. For example, jets are available in different versions with different outlet angles. More than 50 different types of jet heads are already available as the foundation for meeting our customers’ diverse requirements.

Special design

Optionally, we can also offer you the PFW10 and PFW20 with a 90° cable connection. This design is especially suitable for applications with limited space for mounting the jet (the jet is shorter).

Application Examples

- Plasma cleaning and activation of plastics, metals, and glass

- Films and three-dimensional components

- PP headlight housing: precise pretreatment of the flute bonding groove

- Bottle labeling: inline, aqueous waterbased adhesive systems can be used

- EPDM profile: 10-fold nozzle arrangement for lamination on all sides

- Aluminum profiles: arrangement in the nozzle tool as a substitute for pickling and chromating

- Cartons: pretreatment of the longitudinal seam, transport speed up to 600 m/min

Variety of jet heads

Generating plasma alone does not make a successful application, therefore Plasmatreat has a lot of competence and experience in the design of customized jet heads.

Minimum maintenance on the one hand, utmost process reliability on the other hand.

Special design plasma jet: PFW10LT for the gentle treatment of smallest plastic components

The PFW10LT plasma jet is used especially for the pretreatment and cleaning of plastics. Due to its unique design, it operates at low temperatures (<80 °C) and is therefore particularly gentle. The treatment is carried out by a potential-free plasma beam at the nozzle outlet, the Openair-Plasma®. The plasma is generated by a high-voltage discharge inside the jet and transported by air flow to the surface. All high voltage remains inside the jet. Openair-Plasma® is electrically potential-free. Electrically conductive as well as non-conductive materials can be treated with equally high effectiveness.

You want to test our products for your material?

Give it a try: Our experienced application engineers are looking forward working with you to find the best solution for your use case. In our well-equipped laboratories, together we will pretreat your individual parts with our plasma technology and analyse the results.