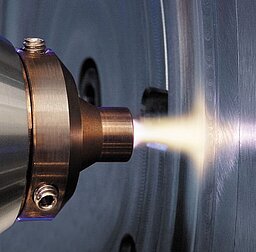

Surface modification using PlasmaPlus® nanocoating

By using nanocoating in the PlasmaPlus® process with atmospheric pressure plasma, substances customized for the area of application are deposited down into the nanostructures of the material surface. A highly-effective functional coating is created, such as a corrosion protection coating or an anti-adherent coating. The materials acquire completely new characteristics. Manufacturing products with selectively functionalized surfaces means a completely new dimension in innovation capability.

Easy to clean: functional coating that repels water and soiling

Plasma coating produces surfaces that are highly hydrophobic so they repel water (lotus effect). They are also dirt-repellent thus have self-cleaning properties without requiring any mechanical cleaning action. Pioneering application areas include coating of automobile components (for example, aluminum wheel rims) or window frontages and glass panes.

Barrier coating – safe protection for food, beverages and medicine

Barrier coatings are an effective way of stopping the diffusion of carbon dioxide, oxygen and water. They can be applied to all types of plastics and in the packaging industry; they make it possible to produce barrier films or PET bottles with a CO2 barrier. For food or medicinal packaging, they provide barrier layers so that the active ingredients and flavorings, as well as quality and characteristics of the contents, are protected.

Self-cleaning and germ-killing antimicrobial functional coating based on titanium dioxide and silver

Depositing photocatalytically-active titanium-dioxide coatings is possible with the PlasmaPlus® process. Under the effect of sunlight and moisture, these coatings have a self-cleaning and germ-killing effect. This application is especially interesting for coating medical and sanitary products since intervals for manual cleaning can be extended or the cleaning dropped all together. Another Plasmatreat research topic is the deposition of antimicrobial coatings containing silver.

Adhesion-promoting functional coating for 2-component injection molding

Plasmatreat is doing intensive work and research on improving rubber-to-metal and plastic-to-metal bonding between in hybrid injection molding. For this purpose nanocoatings with active adhesion are applied to the metal surface, then the plastic component is molded onto the surface. In the future, depositing adhesion-promoting coatings with the PlasmaPlus® process can replace primers containing solvent in automobile manufacturing.

Nanocoating of complex three-dimensional components

By using a combination of Openair-Plasma® technology and PlasmaPlus®, complex 3-D components can be coated using atmospheric pressure plasma. The coating material reaches even areas that are hard to access like deep groove geometries or undercuts. This makes it possible to completely coat populated circuit boards on and under the components.

A global first in injection molding: Anti-adhesion of PUR by Openair-Plasma® only

By nature, PUR foams have a tendency to stick to the injection molding tool. In order to prevent this, the insides of the molds are usually sprayed with release agents, but these can leave traces on the molded parts. Another option is to apply, a permanent coating to the mold, although this requires disassembly, shipping of the tool to a specialty company, and subsequent reinstallation. An expensive and time-consuming process.

System partners Plasmatreat GmbH, market leader in atmospheric plasma technology, and CeraCon GmbH, engineering specialist in foam sealing systems, presented a newly-developed anti-adherent solution at the K 2010 plastics trade show. They showed how Openair-Plasma®atmospheric technology makes it possible to process polyurethane without release agents through in-mold application and in-mold regeneration of the coating. In the PlasmaPlus® coating process, an organosilicon compound is mixed with the plasma. Because of the high-energy excitation in the plasma, the compound is fragmented and deposited on a surface as a glassy coating.

The anti-adherent effect occurs solely due to plasma polymerization on the mold surface. Wet chemical release agents are completely replaced by this environmentally-friendly process, and removal of the mold for recoating is no longer necessary, since old coats do not have to be removed. Regeneration can now occur, for the first time, directly in the injection molding tool.