Strong plastic-to-metal bonds in the injection molding process

Plastic-metal hybrid components are firmly established in industrial manufacturing and are becoming increasingly relevant in an era of lightweight construction. This material combination comes into its own for components whose property profile unites the individual strengths of both materials: The metal provides high strength and stiffness, while the plastic offers greater design flexibility combined with low density.

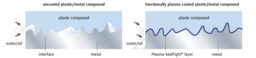

A reliable covalent bond is the key to joining two dissimilar materials to create a high quality, durable and reproducible compound. If not properly sealed, the joint interface between the plastic and metal materials constitutes a risk factor.

Together with plastic compound manufacturer AKRO-PLASTIC GmbH, Plasmatreat has developed a process for hybrid injection-molded components which significantly improves bond adhesion and can be integrated into mass production lines. The atmospheric PlasmaPlus® coating Plasma-SealTight® lies at the heart of this development. This coating facilitates the formation of a covalently bonded joint between the two materials to create a very strong, media-tight hybrid compound.

Plasma-SealTight® process: Reliable, reproducible and environmentally friendly

The Plasma-SealTight® process is designed as an automated inline solution for continuous production systems which can be fully integrated into the injection molding line. All process components within the overall concept (plasma polymer layer, plastic recipe, process parameters) are precisely matched to ensure that the process is reliable and reproducible even at high production capacities.

The first step involves cleaning the surface of the metal inlay to a microfine level with Openair-Plasma®. An adhesion-promoting, corrosion-proof, plasma polymer coating is then applied to the metal surface immediately after cleaning. Both the plasma cleaning and plasma coating process are completed in a matter of seconds and are area-selective, i.e. applied only to targeted areas. The thermoplastic is then injected onto the coated metal in the subsequent injection molding process.

The pretreatment steps used in conventional processes such as solvent-based primers, which are often harmful to the environment, can be completely replaced by the Plasma-SealTight® coating while maintaining quality assurance.

Improved bond strength compared with adhesion promoters

Plasma-SealTight® bonds to the metal (stainless steel, copper, aluminum, steel) at molecular level and at the same time generates organic compounds (functional groups) which ensure a strong adhesive bond between the metal and the plastic.

Tensile shear strengths of over 40 MPA can be achieved between plastic and metal with Plasma-SealTight®. Plasma coating achieves significantly higher bond strength than other processes such as adhesion promoters, laser micro-structuring or etching.

Media-tight hybrid bond

Water can penetrate the boundary layer and spread across the surface of materials that do not have a chemically bonded joint. In combination with oxygen, water corrodes the metal insert in the hybrid compound, leading to failure of the component function or even delamination.

The Plasma-SealTight® effect

The plasma coating prevents the penetration of aggressive media by filling in even the tiniest of cavities and bonding covalently with the metal surface. This protective seal provides a long-time stable barrier to water, salt solutions, oils and gases and prevents these media migrating below the surface.

Benefits of Plasma-SealTight® technology

- increased component quality

- media-tight interface

- can be fully integrated into injection molding line

- high process reliability and reproducibility

- complete elimination of solvents, primers and acids

- very low use of chemicals (precursors)

- no VOC emissions

Durable Plastic-to-Metal Joints in Injection Molding

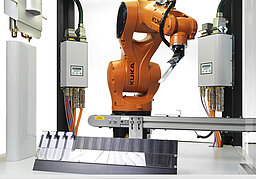

Complete turnkey solution for coating with the Plasma-SealTight® process

The turnkey, fully automated PTU1212 plasma cell was developed by Plasmatreat to enable the shop floor implementation of Plasma-SealTight® technology. The cell, which can be adapted to suit any conventional injection molding machine, enables the very rapid and environmentally friendly inline pretreatment of mass-produced plastic-metal components.

The PTU1212 contains everything the pretreatment process needs, from generator, robot, control technology, PCU plasma control unit and plasma jets to cables and consumables.

Plasma process engineering in the automated manufacturing of hybrid components

Two plasma systems placed side by side perform the plasma treatment. In the first step the robot – or in the case of smaller versions, an XY axis system – passes the metal inlay beneath an Openair-Plasma® nozzle. Here the surface of the inlay is cleaned to molecular level to remove all contamination and create the conditions for optimum wettability. Immediately after cleaning, the second plasma system applies the functional coating to the metal inlay using the Plasma-SealTight® process.

Plasma-SealTight® at a glance

Innovation and cost reduction

- globally available industry solution

- inline use in injection molding production lines (no external transport routes)

- reliable and reproducible process

- high development potential (new material combinations)

- area-selective pretreatment at very high speeds

Increased component quality

- significantly improved bond adhesion

- corrosion protection of metal inlay

- media-tightness in the joint interface

- highly precise and reproducible compounding process ensures consistent product quality

Environment and sustainability

- complete elimination of solvents, primers and acids

- no VOC emissions

- very low use of chemicals (precursors)

- high energy efficiency due to low energy consumption of the plasma unit

- high energy efficiency due to the elimination of transport routes for semifinished components