-

What is Plasma

-

What is Plasma Overview

- What is Plasma

- Plasma Surface Treatment

- Types of Plasma

- Capability of Openair-Plasma®

- Surface Determination

- FAQ

-

-

Industry Solutions

-

Industry Solutions Overview

- Industry Solutions

-

Processes

-

Processes Overview

- Processes

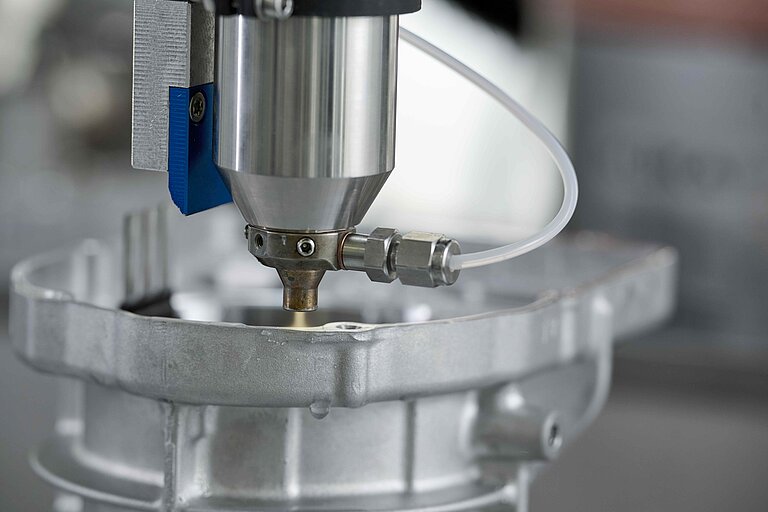

- Bonding

- Printing

- Painting

- 2-Component Injection Molding

-

- Automotive

-

Electronics

-

Electronics Overview

- Electronics

- Cell Phone

- PCB Manufacturing

-

PCB Assembly

-

PCB Assembly Overview

- Conformal Coating

-

- LED

- Displays

- Flexible electronic components

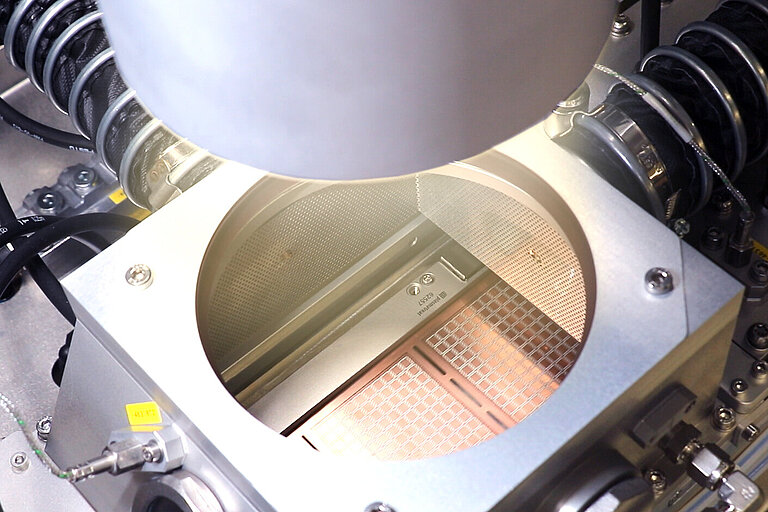

- Semiconductor Packaging

- Power Modules

-

-

Life Sciences

-

Life Sciences Overview

- Life Sciences

-

Medical Technology

-

Medical Technology Overview

- Medical Technology

- Syringe Manufacturing

-

- Chemistry and Biochemistry

- Plasma Medicine

- Medical Disinfection

-

-

New Energies

-

New Energies Overview

- New Energies

- Solar Technology

- Wind Power

- Energy Efficiency

-

-

Consumer Goods

-

Consumer Goods Overview

- Consumer Goods

- Furniture

- Appliances

- Toys for Children

- Sporting goods

- Eyewear

-

-

Packaging

-

Packaging Overview

- Packaging

- Plastic Packaging

- Board and Paper

- Glass and Metal Packages

-

- Textiles

-

Transportation

-

Transportation Overview

- Transportation

- Aerospace

- Shipbuilding

- Trucks and Trailers and Mobile Homes

- Two Wheelers and Motorcycles

-

-

-

Technology

-

Technology Overview

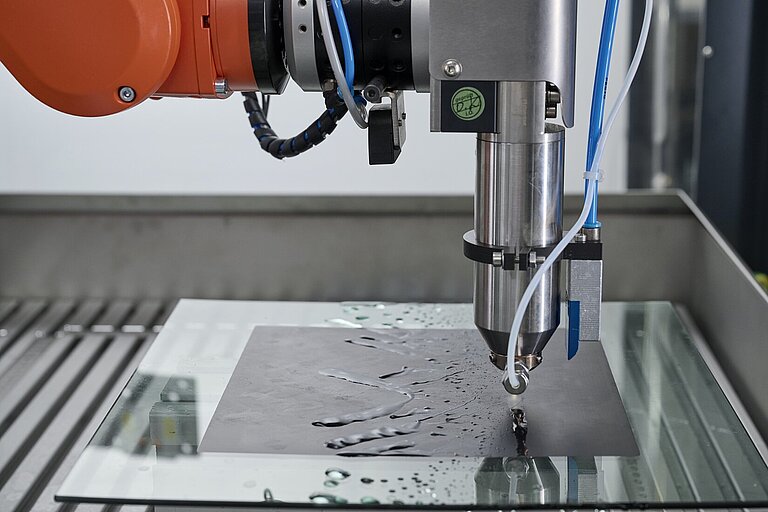

- Technology

- Surface Activation

- Plasma Cleaning

- Plasma Reduction

-

Plasma Coating

-

Plasma Coating Overview

- Plasma Coating

- AntiCorr®

- PT-Print

- PT-Bond

- Functional Coating

- Plasma-SealTight®

-

- InMould-Plasma®

-

Plasma Adhesion

-

Plasma Adhesion Overview

- Adhesion to Metal

-

-

-

Products and Services

-

Products and Services Overview

- Products and Services

-

Products

-

Products Overview

- Products

- Openair-Plasma® Process Monitoring

-

Openair-Plasma® Systems

-

Openair-Plasma® Systems Overview

- Openair-Plasma® Systems

- Inline Oxide Reduction

- Film and Foil Manufacturing

- Coil Coating

- Panel Treatment

- Profile Extrusion

- Robot Systems

-

- Openair-Plasma® Generators

-

Openair-Plasma® Jets

-

Openair-Plasma® Jets Overview

- Openair-Plasma® Jets

- Static Jets PFW10 and PFW20

- Static Jet PFW70 and PFW100

- Rotary Jet RD1004

- Rotary Jet RD2004

- Rotary Jet RD2005

- Rotary Jet RD1010

-

-

Low Pressure Plasma Systems

-

Low Pressure Plasma Systems Overview

- Low Pressure Plasma Systems

- Aurora Standard

- Aurora Plus

- Aurora LC

-

-

Products for Surface Determination

-

Products for Surface Determination Overview

- Products for Surface Determination

- Test Ink Method

- Test Ink online order

- AntiCorr® Test Fluids online order

- Contact Angle Measurement - MSA

-

-

-

Service & Support

-

Service & Support Overview

- Service & Support

- Worldwide After-Sales Service

-

Support

-

Support Overview

- Rent a system

- Book a Demo

-

-

-

-

Plasmatreat Academy

-

Plasmatreat Academy Overview

- Plasmatreat Academy

- Team

- Mission and Vision

- Facilities and Equipment

-

Online PlasmaTalks

-

Online PlasmaTalks Overview

- Online PlasmaTalks

- PlasmaTalks Archiv

-

- Seminars, Training Courses and Events

-

-

Sustainability and Innovation

-

Sustainability and Innovation Overview

- Sustainability and Innovation

- Innovations and Awards

- Research and Development

- Partners

-

-

Worldwide Network

-

Worldwide Network Overview

- Our Worldmap

- Asia Pacific

- Austria

-

Benelux

-

Benelux Overview

- Benelux

- Our Local Team

- Our Office

-

- China

- France

-

Germany

-

Germany Overview

- Germany

- Sales Team Germany

-

- Iberia

- Italy

- Japan

- Korea

-

México

-

México Overview

- Mexico

- Our Local Team

- Our Office

-

- Nordic

-

North America

-

North America Overview

- North America

- Sales Team North America

- Our Offices

- Future-focused Research & Development

- Plasma as a Service

-

- Switzerland

- Türkiye

- United Kingdom

-

-

About us

-

About us Overview

- About us

- Family Business

- Milestones

- Our Mission

-

-

Careers

-

Careers Overview

- Careers

- Job Offers in Germany

- Working Environment

- Benefits

- Getting Started with us

-

-

News and Stories

-

News and Stories Overview

- News and Stories

- News and Press

- Our Success Stories

- Trade Shows and Events

-

Offcanvas Navigation

Your currently selected location is

Global

Company News

Exhibitions

Exhibitions