Plasmatreat Test Inks: Measuring Surface Energy

A simple method to measure the surface energy of various materials, such as plastic, glass, and recycled or composite materials, is the determination using test inks. Plasmatreat test inks are an excellent tool for surface determination, quality assurance during ongoing production, and determination of accurate parameters for plasma treatment. All Plasmatreat test inks are manufactured according to DIN Draft 53364 or ISO 8296.

Used all around the world: Plasmatreat Openair-Plasma® technology cleans, activates, coats and promotes adhesion

Suitable for:

- plastics, metals, glass and natural materials

- foils, sheet metal, textiles, and nonwovens

- paints, laminated cardboard packaging and other hard-to-print surfaces

- the removal of organic waste

- the removal of dust particles

- electrostatic discharging of subassemblies

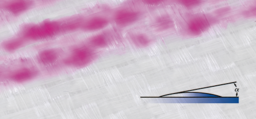

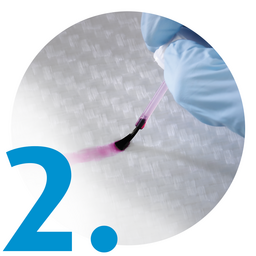

Using Plasmatreat Inks

Important Information on Plasmatreat Test Inks

- Plasmatreat test inks should not be mixed together. Meaningful test results are only possible with original and not contaminated test inks.

- Always reseal Plasmatreat test inks immediately after use. The composition of the test inks can change due to different rates of evaporation of the constituents. For this reason, the test inks have a maximum shelf life of three months, once opened.

- Series B and C Plasmatreat test inks are suitable for PVC. Series A test inks containing formamide, cause PVC to swell which falsifies the results.

- Series A and B Plasmatreat test inks contain toxic chemicals and are produced in accordance with draft DIN standards on surface energy. Please refer to the safety data sheets.

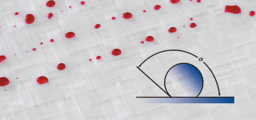

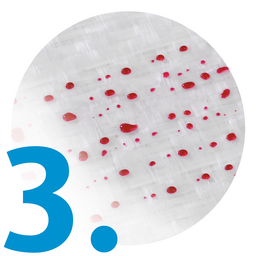

The surface energy of the material is equal to the tension of the test ink last used that showed good wetting for at least 2 seconds.

Series C—Ethanol

- non-toxic

- Over 90% of the test inks sold are C inks

- suitable for all common surfaces

- not harmful to health

- manufactured in accor-dance with DIN 53 364

- available from 28–72 mN/m (in increments of two)

- color: green

Series B—Methanol

- toxic in some cases (depending on surface tension)

- suitable for all common surfaces

- manufactured in accor-dance with DIN 53 364

- available from 28–72 mN/m (in increments of two)

- color: red

Series A—Formamide

- toxic

- also suitable for warmer surfaces

- longer readout time

- not suitable for PVC surfaces

- manufactured in accordance with DIN 53 364 and ISO 8296

- available from 30–72 mN/m (in increments of two)

- color: blue

Evaluating the test results obtained with test inks

-

By critically examining test results and evaluating different measurement techniques, a deeper understanding of surface energies and their impact on adhesive strength can be gained. It can help to optimize processes which are realted to surface treatments.

- Understanding, that surface energy is not the only factor affecting adhesive strength, will allow to consider other variables which may influence the bonding process.

- While the obtained test values are relative and have limited comparability with other measurement methods, it can still be used to make comparisons within the same measurement technique. This enables to assess the relative changes in surface energy and track the substrate's condition over time.

- Plasmatreat test inks are an excellent tool for measuring surface energy during the production quality assurance process. By using these inks and ensuring compatibility between the adhesive/ink and the surface condition, the desired surface energy levels can be effectively monitored and maintained.

- Understanding that the maximum tolerance of the measured surface energy is 2 mN/m (millinewtons per meter) can help assess the reliability of the measurements and set appropriate criteria for acceptable surface energy levels.