Plasma systems for the coil coating process

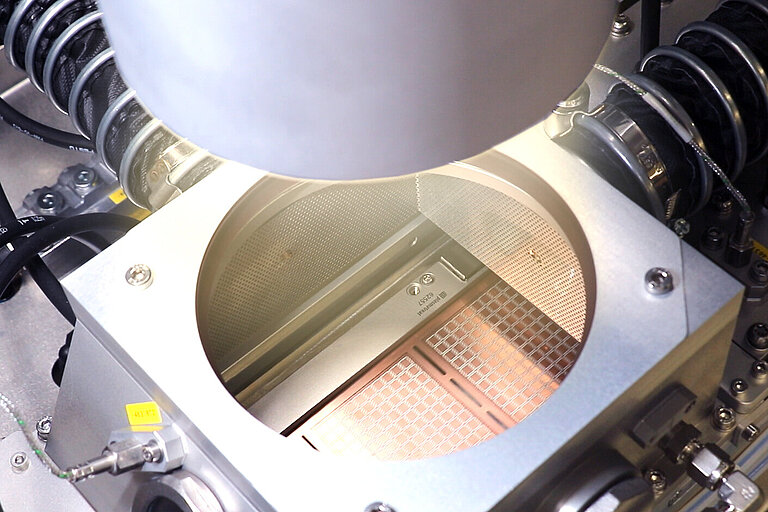

An example of the high efficiency of Openair-Plasma® activation is the manufacture of pre-coated sheet metal (coil coating). This material is needed in the industrial production of household appliances and in the automotive industry.

In the coil coating process, strip metal is provided with a surface coating or varnishing to achieve optimum protection against corrosion and to simplify subsequent production processes. For long-term layer and varnish adhesion, the aluminum strip must first be completely cleaned of rolling oils in an ultrafine cleaning process.

Efficient ultrafine cleaning without chemicals or wastewater

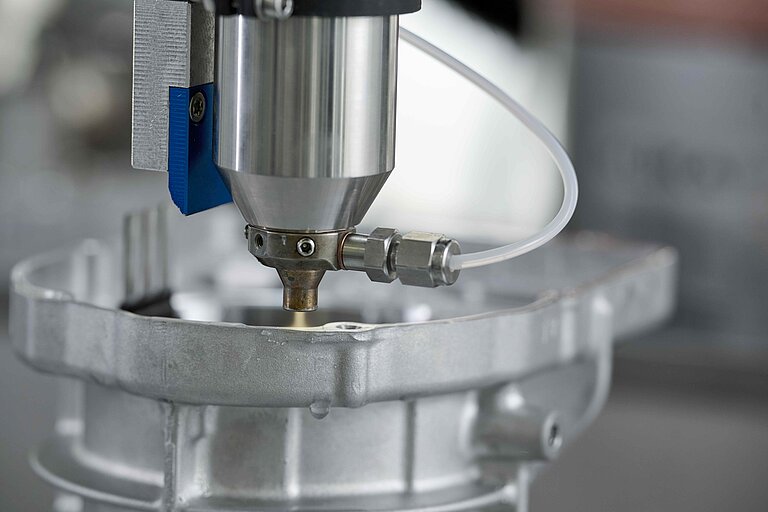

Openair-Plasma® removes all residues reliably and efficiently while activating the material surface for optimal adhesion and a flawless finish. The Openair-Plasma® treatment can be integrated inline directly upstream of the coating station in the rolling mill.

Moreover, the dry plasma process is particularly environmentally friendly. The large amounts of chemicals that would otherwise be required for ultrafine cleaning are omitted entirely.

Also, the time- and energy-intensive drying processes necessary in wet chemical treatment are no longer required.

FEATURES &

ADVANTAGES

Openair-Plasma® systems

for coil coating

- High efficiency in the cleaning of aluminum coils

- Surface activation prior to corrosion protection coating and varnishing

- Saving water, chemicals and wastewater

- Possibility of one-sided or two-sided pretreatment

- Variable nozzle configuration depending on the degree of contamination

- Cost-efficient inline integration

Removing hydrocarbons, increasing the hydrophilicity of aluminum

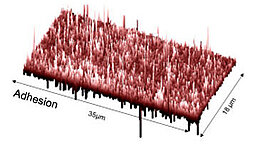

Using Openair-Plasma®, metals such as aluminum can be completely cleaned of unwanted hydrocarbons, such as rolling oils, through the evaporation of volatile components and oxidation to carbon dioxide and water. To investigate the cleaning efficiency of Openair-Plasma® treatment on aluminum, the research company NanoCraft used the very sensitive method of chemical force microscopy. The probe tip was modified using nonpolar hydrocarbon compounds and the measurement was carried out with water as the imaging medium. This ensured detection of even the smallest impurities by their interactions with the probe tip. At the same time, the surface tension of the material can be selectively increased by plasma activation. The increase in hydrophilicity is measurable; the adhesion of coatings and finishes is greatly improved.

Adhesion distribution on aluminum without plasma treatment. Interaction with the probe tip: the surface is covered with oily impurities.

Homogeneous adhesion distribution on aluminum after plasma treatment (hydrophilic). No interaction with the probe tip: the surface is free from oily impurities.

You want to test our products for your material?

Give it a try: Our experienced application engineers are looking forward working with you to find the best solution for your use case. In our well-equipped laboratories, together we will pretreat your individual parts with our plasma technology and analyse the results.