Energy-saving manufacturing processes: more efficient because surfaces are pretreated with atmospheric pressure plasma

Energy that is not consumed does not have to be generated in the first place! Plasma technology contributes to completely replacing outmoded, energy-hungry manufacturing processes with new processes. The drying steps in conventional wet chemistry processes, for example, require far more energy in comparison to the dry inline plasma process (energy-efficient surface treatment).

The same is true for the use of new materials in lightweight construction or in thermal insulation. In many industrial applications, the Openair-Plasma® technique makes possible completely new, shortened, and energy-saving manufacturing processes.

The subject of energy efficiency provides especially clear proof that Openair-Plasma® makes process optimization and with it, significant savings possible in almost all areas of industrial production as an interdisciplinary technology.

Plasma treatment instead of wet chemistry: Environmentally friendly energy savings using dry processes

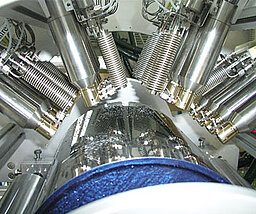

Plasma technology under atmospheric pressure conditions, with its inline capability, makes it possible to completely redesign production processes (process optimization) in many industrial applications. Since the entire surface treatment process runs under dry conditions, it also offers the greatest potential for saving energy. Drying processes that require a lot of energy are eliminated. Besides that, the use and disposal of many toxic chemicals can be avoided.

A method for eliminating drying processes that has been successful for years is plasma coating of workpieces. Plasma coatings provide additional functionalities and often can be implemented at a fraction of the cost compared to conventional coating processes with painting, etc.

Until now, plasma coating was implemented in a low pressure process, for example, with PVD and sputtering processes. Now with the Openair-Plasma® process, combined with PlasmaPlus®, plasma coating can be applied under normal pressure without separate chamber systems.

Energy savings with lightweight construction: secure bonding of new materials using atmospheric pressure plasma

The stated goal of lightweight construction is to save resources in the manufacturing, assembly, transport and use of a product. In lightweight material construction, this is done by substituting traditional materials like steel with new materials and material composites like GRP (glass-fiber-reinforced plastics) or CRP (carbon-fiber-reinforced plastics). This not only reduces raw material costs, it also increases energy efficiency in production, while the logistics costs are noticeably reduced as well.

In designing airplanes, for example, saving weight is critically important. One kilo of weight saved results in a savings of 5000 tons kerosene in the course of a vehicle life. The same is true for railroad vehicles, passenger cars and especially trucks. Modern trailer designs offer a maximum of payload with reduced curb weight.

These requirements can be achieved by using lightweight construction and the combination of different material composites. Plasma treatment makes possible material combinations that are completely new in some cases (plasma bonding technology). The two leading German companies in trailer manufacturing have used Openair-Plasma® technology from Plasmatreat successfully for years.

Examples of efficient use of Openair-plasma® bonding technology in lightweight construction:

- Secure bonding of different materials (e.g. plastic-metal assemblies, sandwich components or fiber-reinforced materials) using plasma bonding technology

- Structural bonding of truck superstructures

- Panel treatment for shipbuilding

- Profile wrapping of WPC lightweight construction panels in the furniture industry

- Researching new types of materials (nanoprocesses, nanocoating)

Thermal insulation with sandwich elements: secure joining of plastic and metal surface layers with PUR foam (polyurethane)

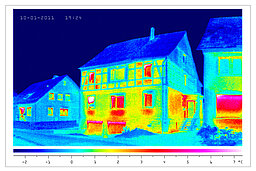

Thermal insulation of buildings is one of the best opportunities for saving primary energy. A modern method for this is applying additional paneling and insulation with sandwich panels. In winter, this reduces heat dissipation from the building, which also reduces heating costs. On the other hand, in summer the insulation prevents unintended heating of living, work and storage spaces.

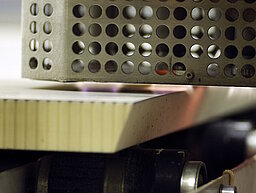

In commercial building construction, sandwich superstructures are used that are made of steel cover layers with insulating polyurethane cores. In addition to providing thermal insulation, these sandwich elements simultaneously have a static function as an outer wall and for holding the windows and doors. The secure bonding of the PUR foam to the top layer makes a critical contribution to the static properties of this type of commercial building wall.

In particular, the introduction of R141 propellants, pentane and water-blown foams that replaced R11 propellant, which is a concern for the climate, led to serious problems in adhering PUR foams to the top layer.

Large-area Openair-Plasma® pretreatment of the panels results in a definite improvement in bonding the PUR foam to plastic, glass and metal (plasma systems for surface activation). Today, plasma technology is in use with great success worldwide in the production of continuous double-line systems and discontinuous systems for manufacturing panels.

Interesting success stories in this field

Energy-efficient processes: plasma treatment means low processing temperatures and high process speeds

When different materials are combined, such as in bonding, laminating or painting, surface tension and surface cleanliness are critically important for reliable adhesion. To achieve good adhesion characteristics, the materials are often brought to a specific necessary processing temperature in the manufacturing process. Generally these are very energy-intensive processes. In contrast, plasma treatment is not only an especially effective method for surface pretreatment, it is also an energy-saving alternative.

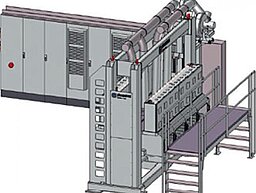

The use of Openair-Plasma® atmospheric pressure plasma makes a definite reduction in operating temperatures possible in many applications. The heating process can usually be shortened or even eliminated completely. The same is true for drying ovens when alternative coating systems (like UV-curing systems) are used.

An example of success in coil coating: By using Openair-plasma® cleaning (ultrafine cleaning) and plasma activation, it is possible to use UV-curing paints. The complete system configuration is reduced to 25% of the scope of a conventional system.

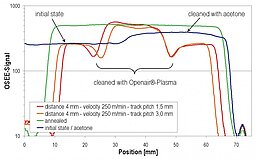

Plasma cleaning instead of annealing: saving energy during annealing and furnacing of metals, glass, ceramic

The annealing process that is still frequently used in various industries is extremely time and energy consuming compared to Openair-plasma® pretreatment. Often products like aluminum foils need to be cleaned of light greases are treated in annealing ovens for several days at high temperatures to degrade and evaporate oils and greases.

Because of the especially effective heat transfer in the plasma process, the combination of Openair-plasma® cleaning with the annealing process results in a significant reduction in process times. In fact, they are reduced from 72 hours to 10 minutes! And thermal treatment can often be eliminated completely.

Our next PlasmaTalks and Events

Upcoming Exhibitions and Events

Get to know Plasma up close at our trade fairs and events!

FENSTERBAU FRONTALE

Hall 3, Booth 3-150

NürnbergMesse GmbH

Messezentrum

90471 Nürnberg

Germany