Plasma treatment of giant wind power rotors – efficient, automatic, reproducible

Wind power systems convert the kinetic energy of the wind directly into electrical energy. In windy locations, these systems make a significant contribution to energy production. Besides the construction shape, the efficiency of such a wind power system also depends in particular on its size. Current systems are built for production of up to 10 megawatts and with blade profile lengths of up to 90 meters.

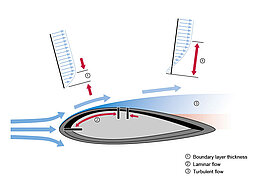

The technology required for manufacturing and constructing a wind power system is similar in many ways to that of aircraft construction. The cross section and the mechanical stability, as well as the air flow around the blade profile, are based on the design of aircraft wings. The circumferential speeds, which are especially high at the blade tips, create extreme materials stress – like air turbulence in the ultrasound range or an accumulation of ice – just as in air travel.

Special requirements for manufacturing advanced wind power rotors:

- Lightweight materials

- High-strength structures

- Smooth turbulence-free surfaces

- High surface quality and stability

Almost the only way these requirements can be fulfilled is by using GRP (glass-fiber-reinforced plastic) and CRP (carbon-fiber-reinforced plastic). Like in the aircraft industry, atmospheric plasma treatment supplies especially effective process solutions here.

Highly-effective application areas of Openair-Plasma® treatment for manufacturing wind power blades:

- in the fiber pretreatment

- in the laminating process

- in half shell bonding

- in surface treatment of the manufactured components (surface finishing)

Painting rotor blades for wind turbines: Secure paint bonding on CRP after plasma activation

The state of the art in surface pretreatment for CRP rotor blades is mechanical roughening and cleaning with solvents. This process leads to results that are far from uniform, it is environmentally hazardous, and it requires a lot of manual effort.

Typical for CRP components is the different heat conductivity between the fibers themselves and the fiber matrix. Treatments that apply higher temperatures, such as in flaming or laser treatment, can destroy the characteristics of the composite surface.

With Openair-Plasma® technology, plasma treatment of even large-scale components is possible without problems. This opens up new possibilities for manufacturing rotor blades made of CRP for wind turbines.

An Openair-Plasma® treatment, especially with the plasma nozzle RD2005, provides uniform surface activation without the application of heat. The result of such plasma activation is improved paint adhesion with uniform paint flow for friction-free and high-efficiency use of the rotor blades.

PT-Release plasma coating: demolding of fiber composite components without release agents (CRP and GRP)

Generally, rotor blades are manufactured as half shells in a laminating process with CRP and GRP mixed construction. Application of a separating layer in the mold is indispensable so the finished component can later be removed from the mold. Conventionally, this is achieved with chemical release agents and has to be applied again after each demolding. In the demolding process, traces of this separating layer are transferred to the component. These must be removed without residue before the subsequent painting.

Plasmatreat has developed a simple and efficient solution for reliable demolding of CRP and GRP components without chemical release agents: the PT-Release process that is used to apply a plasma polymer using Openair-Plasma®.

Simple and efficient demolding of CRP and GRP components with PT-Release plasma coating

- Before the material layers are applied, the molds are coated with the PlasmaPlus® process by robot

- The coating application is controlled with uniform coating thickness

- Functional strength: currently approx. 50 demoldings possible with only one plasma coating

- After the demolding and before painting, remaining release agents are completely broken up and removed with Openair® plasma cleaning

PlasmaPlus® functional coating of rotor blades: corrosion protection and better aerodynamics for more yield

The laws of aerodynamics apply just as much to the efficiency of rotor blades in wind power systems as they do to aircraft, where air friction on the surface of the wings and on the fuselage determines the efficiency of the aircraft. Microstructuring and the application of very hydrophobic and textured surfaces reduce the friction resistance. One model for this is the way the dolphin moves in water (dolphin skin).

Our next PlasmaTalks and Events

Upcoming Exhibitions and Events

Get to know Plasma up close at our trade fairs and events!

FENSTERBAU FRONTALE

Hall 3, Booth 3-150

NürnbergMesse GmbH

Messezentrum

90471 Nürnberg

Germany