Precise functionalization of textiles

Fabric can acquire entirely new material qualities by creating new functionalities, like self-cleaning finishes, bioactive surfaces, and flame retardant properties, for example. Entirely new application possibilities are the result. In many cases, conventional materials can also be replaced by less expensive alternatives.

Added value with plasma coating – precise functionalization of textiles with PlasmaPlus®

Textiles with functional coatings are required for the manufacture of sports and recreational clothing, protective clothing, barrier textiles, medical or hygiene textiles or for membrane in the context of textile architecture. PlasmaPlus® from Plasmatreat offers a particularly effective process for this that is easy to integrate inline, with the widest range of nano-coatings for fabric that can be economically applied.

PlasmaPlus® coating offers many advantages and options for functionalizing fabric:

- High deposition rate with low material stress

- Process that can be universally modeled, from hydrophilic to hydrophobic

- Application of coats that repel oil and water

- Creation of coatings with long-term stability

Non-stick plasma coating for textiles

Strongly hydrophobic finishes on textiles have been applied in low pressure plasma processes for many years now. Because this involved elaborate chamber processes, however, this kind of non-stick plasma coating was reserved only for special technical textiles.

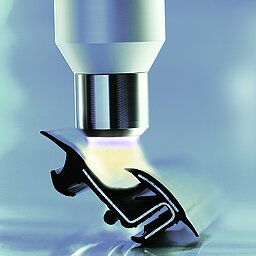

Openair-Plasma® with PlasmaPlus® makes plasma coating possible under atmospheric conditions. This means that non-stick coating can be implemented inline, for instance, in continuous production processes, without separate chamber systems.

Many applications can be revolutionized with this technology. For instance, it is possible to set up hydrophobic finishes directly in large-scale laundries.

Anti-bacterial textiles with long-term stability using plasma coating with titanium oxide

Operating room linens must be sterilized, but it is also desirable to apply a finish with long-lasting anti-bacterial action that inhibits germs as well. Today, this is accomplished by suspensions containing titanium oxide.

PlasmaPlus® nano-coating makes it possible to apply that type of textile coating in a highly effective inline process in which the titanium-oxide suspension is precisely added to the plasma process. The plasma jet cleans the surface of the fabric while simultaneously applying nano-layers of anti-bacterial suspension to the fibers.

This process makes it possible to apply a highly effective and economical functional layer with long-term stability and germ-inhibiting qualities to textiles.

The thickness achieved through PlasmaPlus® is controlled and reliable in the laboratory as well as in industrial usage.

Natural fibers without shrinkage – using conditioner-free PlasmaPlus® textile coating

Fiber preparation and conditioners form a film on fiber surfaces that reduces surface friction during production with natural fibers. Without this protective film it would be impossible to achieve high production speeds in the textile industry. But these same conditioners play a major role in shrinkage of natural fibers when the fabric is cleaned.

Openair-Plasma® technology facilitates organic silicon fiber preparation. This unique plasma coating effectively protects the fibers and prepares them for high-speed production.

Since no chemical conditioners are used in this new process, the fabric produced will not shrink in subsequent cleaning. The consumer is rewarded with higher quality.

Plasma makes possible secure flocking for high-quality textile finishes

Flocking refers to the process of depositing short monofilament textile fibers on a substrate previously coated with glue. The surface thus acquires a high-quality velvet or velour effect. Flocking is typically performed in an electrostatic field which accelerates and aligns the fibers so that they remain vertical in the glue bed. The bonding of the glue bed on the fabric substrate is an important factor in the quality of the flocking.

Fabric pretreatment with Openair-Plasma® substantially increases the bonding capability of the modified surface and is therefore a highly effective processing factor in textile finishing.

Openair-Plasma® has proven its value in the automobile industry as well, where it has been used as a pretreatment in flocking processes for years (such as flocking on EPDM, glove compartments or fabric itself).

Our next PlasmaTalks and Events

Upcoming Exhibitions and Events

Get to know Plasma up close at our trade fairs and events!

PlastIndia Delhi

Booth / Hall H4GM-D17

Bharat Mandapam

New Delhi India

FENSTERBAU FRONTALE

Hall 3, Booth 3-150

NürnbergMesse GmbH

Messezentrum

90471 Nürnberg

Germany

PaintExpo

Hall 1, booth 1210

Messe Karlsruhe

Messeallee 1

76287 Rheinstetten

Germany