High standards for children’s toys – Openair-Plasma® means safe processing and ink adhesion.

“Printed ink that chips or flakes off a toy can quickly land in a toddler’s stomach." That statement by a well-known toy manufacturer is indicative of the high safety standards required of children’s toys. This means that the ink systems used must comply with the same requirements as those applied to food colorants. At the same time, no toxic stabilizers, like lead, can be used in the production of plastic parts for toys.

Openair-Plasma® for Consumer Products: Toys

So innovative manufacturing processes are required to ensure quality adhesion of printing ink, while also meeting the general challenges of cost-efficient manufacture of the toy.

Using Openair-Plasma®, the high surface tensions required for processing the most diverse materials can be precisely achieved, and most importantly with a purely physical process, free of chemicals. Water-based inks adhere beautifully with long-lasting stability.

An overview of more advantages:

- Alternative materials can be used, such as recycled materials;

- Expands the spectrum of applications for adhesives;

- New, lean manufacturing procedures, such as plasma sealing of furniture edges; and

- Uniform quality during manufacturing, less scrap.

Cost-effective and extremely flexible: Openair-Plasma® facilitates 2C injection molding of children’s toys that is free of toxic materials

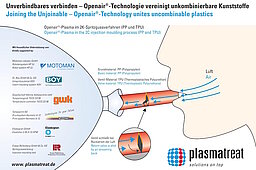

Two-component (2C) injection molding refers to a two-stage manufacturing process using injection molding. First, a hard component is formed that is then coated selectively with a soft component in a second step. If the materials are compatible, these two components form a strong bond.

This process has been rarely used in the manufacture of children’s toys, however, because only certified materials free of any toxins can be used, similar to medical technology. But as a rule, soft components don’t bond well to such materials.

With Openair-Plasma® pre-treatment, however, 2C injection molding can be used by the toy industry without worry and without toxic materials. This plasma system is integrated directly in the extrusion tool and selectively modifies the exact spot where the soft component will be subsequently bonded (plastic bonding agent).

Our next PlasmaTalks and Events

Upcoming Exhibitions and Events

Get to know Plasma up close at our trade fairs and events!

FENSTERBAU FRONTALE

Hall 3, Booth 3-150

NürnbergMesse GmbH

Messezentrum

90471 Nürnberg

Germany