Openair-Plasma® allows for fully automated cleanroom painting

Modern touchscreens, LCD displays and TV screens make high demands on production processes as the plastic parts must be provided with highly transparent scratch-proof and anti-static coatings before they are bonded. The high degree of automation in the electronics industry demands a surface treatment process that can perform inline with the utmost reliability, delivering a high degree of activation at high speed.

Crystal-clear displays: plasma treatment for flawless protection and functional coatings

The microfine atmospheric plasma cleaning and activation of the Openair-Plasma® process provides highly effective solutions for the electronics industry. Plastic displays are plasma-treated directly before applying the antistatic and scratchproof coating, ensuring high surface energy for even coating and a flawless finish with fewer rejects. The treatment is suitable for both selective and large-area pretreatment, improves coating quality and adhesion with fewer errors, offers better process control than wet chemical methods, simplifies the process chain, and is environmentally friendly since it produces no waste products.

Significantly less scrap when Openair-Plasma® micro-cleaning is used prior to anti-static coating of TV screens

The Openair-Plasma® process has been used for years by leading manufacturers to improve the quality of their anti-static coating on cathode ray tubes. Now the same quality is available in the manufacture of LCD and LED monitors.

Even the smallest particle of dust embedded during coating can mean an entire component must be scrapped. Even when a cleanroom is used, integrating micro-cleaning with Openair-Plasma® results in additional, significant reduction in scrap rates.

Glass-clear appearance, and scratch-proof surfaces with Openair-Plasma® treatment

Displays are coated with a special coating during the last stage of the manufacturing process. This coating improves scratch resistance and enhances the quality of surfaces such as those made of PC (polycarbonates) and PMMA (polymethyl methacrylate). To ensure that this coating adheres, surfaces must be pretreated. Openair-Plasma® offers the perfect inline process to accomplish that, replacing elaborate processing that uses low-pressure plasma treatment. This means a significant simplification of the process chain in the manufacture of displays and a substantial reduction in scrap rates.

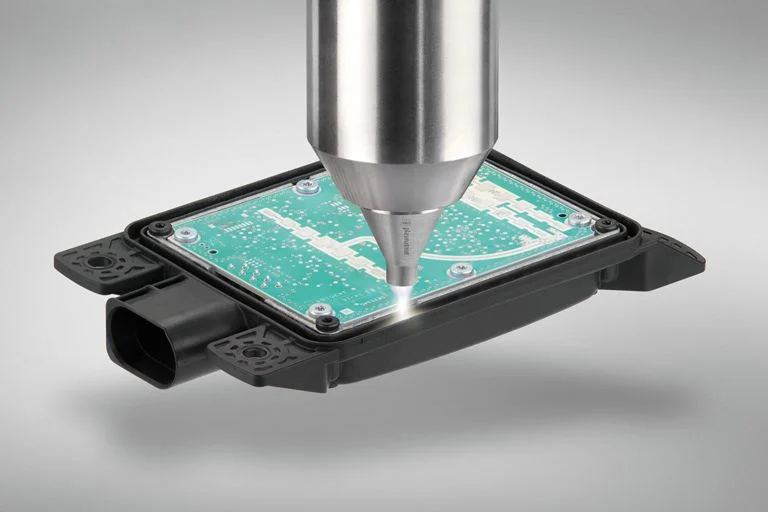

Plasma cleaning ensures strong bonding of LCD displays

Displays for digital gauges and indicators, radios, on-board computers, mobile telephones, and laptop monitors are bonded with a flexible film or conductive rubber, using a hot sealing process. The film forms a flexible connection between the circuit board and the contact surface that generally comprises two thin panes of glass. The simple principle used in Openair-Plasma® pre-treatment removes every trace of carbohydrates and impurities from these contact surfaces. This results in a uniformly high bonding quality and a reduction of scrap rates. The same applies to this process with hot bar soldering and micro-welding.

High expectations: unbreakable and scratch-proof display surfaces

Modern smartphone and tablet displays must be thin, lightweight, attractive, and durable. While tough glass such as Gorilla Glass offers high scratch resistance, it can still break. To achieve both strength and lightness, displays are increasingly made of polycarbonate. Thanks to a Plasmatreat surface coating applied via low-pressure plasma, polycarbonate gains an ultra-hard, scratch-proof surface, making it ideal for handheld device displays.