Plasmatreat's Plasma Technology Creates Stronger, More Durable Appliances

Appliances like washing machines, stoves, and dishwashers are manufactured in large numbers and are generally subject to a short product lifecycle. On the other hand, there are high requirements for joined materials with long-term stability as well as cost-efficient processes. This has been reflected in increasing attention to adhesive bonding within the manufacturing process, with the aim of achieving simple and cost-effective durable joining of materials. Beyond that, the long-term stability of imprinting is important, especially given the wear on appliances caused by moisture and alkalis.

Topics on this Page:

Advantages Bonding washing machine parts Bonding handles and hinge strips

Pad printing on sensitive operating displays Anti-fingerprint nano-coating

Openair-Plasma® pretreatment can be automated using robots and easily implemented in the manufacturing process. Once it has been integrated, this system delivers reliably monitored and reproducible surface pretreatment with the push of a button.

Plasmatreat is constantly developing new, unique Openair-Plasma® applications in successful partnerships with major international manufacturers in the appliance industry.

Advantages of pretreating appliances with Openair-Plasma®:

- Material costs reduced with the option of using alternative materials, such as polypropylene (PP)

- Manufacturing costs reduced by avoiding chemical bonding agents (no primer required) and economizing on manual production steps

- Quality improved by precise, selective activation

Minimal maintenance effort on the one hand and full process safety on the other.

Plasma treatment prior to bonding washing machine parts – door, drum, cover panel, counter weight

Openair-Plasma® has a wide range of applications in the washing machine manufacturing process. From the joining of the all-polypropylene plastic parts involved in washing machine doors, through bonding plastic strips on composite panels, bonding metal to metal in drums, to the bonding of dynamically highly stressed counter weights made of polymer concrete – Openair-Plasma® sets new standards in pretreatment.

There are practically no limits to the possibilities offered by Openair-Plasma® pretreatment since, when it’s combined with the right adhesives, highly durable joining can be achieved with almost any material.

Interesting success stories in this field

Bonding handles and hinge strips in oven doors – highly durable joining of glass and ceramics

Bonding ceramic-coated glass to metal poses a challenge for pretreatment of the surfaces involved. The process of direct glazing taught the automobile industry long ago that even the smallest traces of contamination or dirt can reduce the long-term stability of the adhesive bond and lead to total failure.

Openair-Plasma® treatment of both the metal and the glass ceramic material simplifies and reliably stabilizes this process, and makes manual cleaning with solvents unnecessary.

In terms of the manufacturing technology involved, this also means that elaborate suction equipment to recover solvents is no longer needed.

Effective pretreatment – Openair-Plasma® for high-quality pad printing on sensitive operating displays

An attractive look and abrasion resistance are quality features in demand for control panels on washing machines, ovens, and other appliances. High-gloss white polypropylene components are used that will then be pad printed. Pretreatment is required, however, to ensure that solvent-free ink will adhere securely to these non-polar plastics.

Conventional pretreatment methods (such as corona or flame) are not much help in pretreating high-gloss polypropylene (PP) because they generally result in thermal destruction of the gloss surface.

Openair-Plasma® treatment offers the ideal solution; rotating plasma jets achieve high surface activation with the lowest possible thermal impact.

Invisible anti-fingerprint nano-coating to protect high-quality stainless steel facades

Surfaces of metalized plastic or stainless steel (such as on ovens, dishwashers, refrigerators) can have an especially attractive decorative impact. Without finishes on those surfaces, however, they would soon be unsightly, corroded by finger prints or cleaning agents.

The PlasmaPlus® process provides long-term protection with new, invisible nano-coatings that can also be combined with anti-bacterial effect. These nano-coatings are applied inline in final processing.

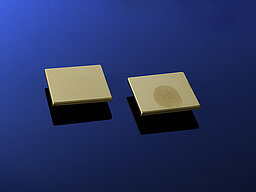

Anti-fingerprint coating from Fraunhofer IFAM – Innovative nanocoating to reduce the visibility of fingerprints:

The coating is distinguished by its ability to maintain surface characteristics – such as gloss and roughness – and is especially suitable for matte surfaces made of metal or plastic.

The underlying process developed by the Fraunhofer IFAM institute consists of two stages. A liquid is first applied in a thin film which is then made to crosslink by plasma or light (excimer technology, Smart Plasma process). © Fraunhofer IFAM

Energy class A++: Energy-efficient dishwashers using hydrophobic low-pressure plasma coating

Household appliances are assigned to classes based on their energy efficiency. For dishwashers it is important, for example, that cleaning and drying normal dishes with normal soiling do not exceed a specific level of energy consumption. The number of water drops that remain inside the appliance significantly determines the classification into an energy efficiency class.

Plasma coating with hydrophobic characteristics (plasma polymerization) makes an important contribution here. Because of the lower surface tension of the hydrophobic functional coating, water drops flow reliably from the walls, dishes, and silverware bin, and the drying process is measurably shortened.

Our next PlasmaTalks and Events

Upcoming Exhibitions and Events

Get to know Plasma up close at our trade fairs and events!

FENSTERBAU FRONTALE

Hall 3, Booth 3-150

NürnbergMesse GmbH

Messezentrum

90471 Nürnberg

Germany