JEC 2026: Reliable Adhesion of Composite Materials with Plasma Technology

PLease download press release and image here

At JEC World 2026, Plasmatreat GmbH will present its plasma technology for the industrial pretreatment of composite materials in Hall 5, Booth G65, in Paris from March 10 to 12, 2026. The focus will be on the reliable adhesion of composite materials with plasma technology by using compressed air and electricity to improve the processing of lightweight materials. The focus will be on applications in the aerospace and automotive industries, where fiber-reinforced plastics and hybrid material systems are becoming more relevant. Visitors will be able to see firsthand how carbon fiber reinforced plastic (CFRP) and thermoplastic components are prepared with plasma for subsequent processes, such as bonding, painting, or sealing. Headquartered in Steinhagen, Germany, Plasmatreat GmbH is a leader in developing and manufacturing industrial plasma technology under atmospheric and low-pressure conditions.

Processing Challenges of Composite Materials

In the aerospace and mobility industries, lightweight composite materials, such as carbon fiber reinforced plastics (CFRPs), thermoplastics, and hybrid structures, are being used more frequently to reduce weight, increase efficiency, and improve performance. However, the low surface energy of these materials often makes it difficult for adhesives, coatings, and sealants to adhere reliably. Therefore, targeted pretreatment of the surfaces before further processing is essential.

Conventional methods, such as mechanical grinding or the use of chemical primers, often have limitations when it comes to large or geometrically complex components. These methods are difficult to control and automate, time-consuming, and subject to environmental and occupational safety regulations.

Plasma Technology for Cleaning, Activation, and Coating

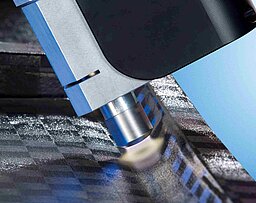

Plasmatreat's Openair-Plasma technology operates under atmospheric pressure and uses only compressed air and electrical energy to enable selective, reproducible surface cleaning and activation. It removes organic contaminants and increases surface energy without altering the material's fundamental properties. A new application in the open air sector is HydroPlasma, which introduces distilled water into the plasma jet. This effectively and reliably removes organic and inorganic residues without damaging the material surface.

In addition to atmospheric plasma treatment, Plasmatreat relies on its Aurora-Plasma low-pressure plasma technology for particularly uniform, full-surface treatment in the aerospace industry. Complex and large-format components are cleaned and activated homogeneously under defined process conditions in closed vacuum chambers. This process is ideal for components that are structurally significant and require high levels of reproducibility, process stability, and quality assurance.

PlasmaPlus technology can apply nano-thin functional coatings at atmospheric or low pressure. These coatings can be used as environmentally friendly bonding agents, for example, and are an alternative to conventional chemical primers.

Process Reliability and Quality Assurance

In the industrial processing of lightweight materials, quality assurance and the reproducibility of treatments are important for manufacturers. Plasmatreat uses its Plasma Control Unit (PCU) to monitor and document relevant process parameters, such as plasma power, gas flow, temperature, and treatment speed, in order to achieve this. These features enable consistent treatment quality, support quality assurance, and facilitate the integration of plasma technology into automated production lines and qualified manufacturing processes.

Plasma Live Demonstration at JEC World

In Hall 5, Booth G65 in Paris, Plasmatreat will demonstrate Openair-Plasma treatment live. Plasma experts will activate CFRP and other composite materials in front of visitors. They will demonstrate the effect of plasma activation and the increased wettability associated with the treatment using various methods. The demonstrations will show how adhesion processes in bonding, painting, or sealing can be stabilized, even with complex component geometries. Visitors are also invited to discuss specific applications for Openair-Plasma or Aurora-Plasma directly with the experts on site.

A Wide Range of Applications for Sustainable Technology

Plasmatreat's plasma technology is used throughout the aerospace industry's value chain, including engine and structural components, fuselage and wing parts, and interior and functional components. Both large-area treatments and selective applications, such as in adhesive grooves, are possible. Improved adhesion increases resistance to corrosion, erosion, and mechanical stress, which can extend the service life of coatings.

Plasmatreat's plasma processes do not require solvents or VOCs, generate no hazardous waste, and can be integrated into existing production environments. Thus, they meet the industry's key requirements for environmental compatibility, automatability, and process stability in the processing of modern composite materials.

Visit Plasmatreat at booth G65 in hall 5.