Openair-Plasma® Technology for Battery and Automotive Applications

Please download press release and images here

At Battery Cells & Systems Expo 2025 (July 9-10, Birmingham), Plasmatreat UK, a subsidiary of Plasmatreat GmbH, based in Steinhagen, Germany, will be presenting surface pre-treatment with Openair-Plasma® and functional nano-coatings with PlasmaPlus® live on booth 1440. The focus will be on applications in the battery and automotive industries - from cleaning prismatic, cylindrical or pouch cells to reliable surface activation and coating. Plasma technology is used to increase surface energy before further processing such as bonding, painting, coating or sealing.

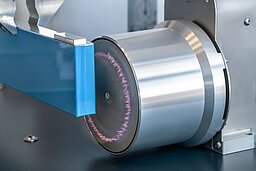

The plasma experts from Plasmatreat UK are bringing various systems and equipment to Birmingham, including a Plasma Treatment Unit (PTU). This compact system will allow visitors to experience Openair-Plasma® and PlasmaPlus® technology live, especially for applications in the emobility sector. Whether it's the entire surface of battery cells, contact points, or the sealing surfaces of housings—numerous process steps in battery production can be reliably covered with Openair-Plasma® and PlasmaPlus®.

Plasma as a pretreatment for strong bond

Atmospheric pressure plasma is a high-energy, ionized gas that is used specifically for the pre-treatment of material surfaces, for example to increase the wettability of surfaces so that adhesives or coatings adhere to the materials for a long time. Using only compressed air and electricity, it enables ultra-fine, dry and residue-free cleaning of glass or metal, for example, before the application of insulating film or coating on prismatic cells. Foils or plastic coatings can be activated by plasma in order to bond them reliably to each other or to the battery housing. Functional coatings can be applied with the PlasmaPlus® applications. For example, AntiCorr® provides environmentally friendly corrosion protection on the sealing surfaces of battery housings and reliably protects against infiltration corrosion. The AntiCorr® process has already been extensively tested and has successfully passed the usual climate tests and salt spray tests, such as the PV1209 or MeKo-S test.

By removing impurities, increasing surface energy and improving adhesion, Plasmatreat's plasma solutions support critical steps in battery manufacturing, such as

- Cell-to-cell bonding: Plasma activation improves adhesion for structural bonds and thermally conductive bonded joints.

- Corrosion protection: PlasmaPlus® AntiCorr® coatings provide protection against infiltration corrosion for battery housings, terminals and other critical components.

- Wire bonding and contact cleaning: Openair-Plasma® ensures reliable electrical connections by removing residue from battery terminals.

- Innovative insulation processes: Plasma treatment enables direct coating applications as an alternative to costly film wrapping.

Plasma as a sustainable alternative to primer and wet chemistry

Compared to traditional processes such as primer application or wet chemical cleaning, plasma technology offers numerous advantages: it is dry, VOC-free, non-contact, targeted and fully inline-capable. “Our customers benefit not only from increased process reliability and reproducibility, but also from reduced operating costs and a more sustainable production process,” says Jonathan Fisk, General Manager of Plasmatreat UK. “Especially in battery production, where precision, adhesive strength and reliable, durable products are essential, plasma is a real game changer.”

Live demonstration and individual consultation

Fisk and his team cordially invite interested trade visitors to bring samples to stand 1440 and discuss individual challenges. The live demonstrations will impressively show how flexibly and efficiently plasma can be integrated into modern production lines - without any chemicals and with maximum process reliability. The experts from Plasmatreat UK will be demonstrating how the treatment works and the effect of plasma on surfaces live with various materials, e.g. metal or various difficult-to-process plastic materials, and subsequent tests with test inks or water, for example.