Openair-Plasma® creates unimagined solutions - even on large areas

Application directly on site: Openair-Plasma® facilitates direct surface pretreatment at the shipyard

Corrosion protection, lightweight construction and insulation are the most demanding challenges in shipbuilding. Here plasma technology opens whole new options to meet those challenges.

Openair-Plasma® means pretreatment can be performed in atmospheric conditions. This in turn means that entire components on completed ships and tankers can be treated with plasma directly on site. Fully assembled components can be completely pretreated for subsequent coating or for the application of insulation.

Advantages of Openair-Plasma® treatment in shipbuilding:

- Considerable cost savings stemming from improved corrosion protection

- Uncomplicated application, even for large-area pretreatments

- Coating pretreatment without use of chemicals (purely physical process)

Interesting success stories in this field

Bonding and painting lightweight panels for ship interiors - without any solvents, thanks to plasma treatment

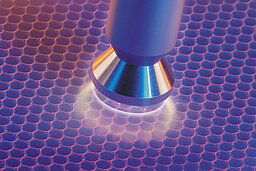

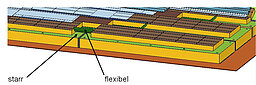

Honeycomb or sandwich elements are preferred for developing modern lightweight panels for walls, ceilings, dividers and complete cabins in ship interiors. These materials are light, strong, and particularly resistant to humidity. The exterior surfaces of the materials must be joined to one another securely, free of bubbles, and evenly.

Surface pretreatment with Openair-Plasma® provides efficient plasma activation with non-polar materials, such as recycled materials or compounds. Plasma treatment is ideal for pretreating top layers when building up layers and in subsequent painting or varnishing processes.

Ship launch in Saint-Nazaire: reliable insulation for liquefied natural gas (LNG) supertankers using Openair® Plasma

As resources become more and more scarce, natural gas deposits are increasingly tapped decentrally. The only way to transport this liquefied gas to refineries is supertankers. Gas cooled to -1630C in the tanks on LNG supertankers must be prevented from coming in contact with the steel walls of the tanker’s hull, which would then become brittle and shatter like glass.

To achieve 100% impermeability, the extremely tough impermeable sheeting used for insulation is pretreated with plasma and bonded with adhesive directly on site when the tank interiors are lined. This large-area surface pretreatment with Openair-Plasma® made it possible to launch these LNG supertankers.

Our next PlasmaTalks and Events

Upcoming Exhibitions and Events

Get to know Plasma up close at our trade fairs and events!

AMPER

Hall F, booth number F224

Výstaviště 405/1

603 00 Brno

Czech Republic

FENSTERBAU FRONTALE

Hall 3, Booth 3-150

NürnbergMesse GmbH

Messezentrum

90471 Nürnberg

Germany