HydroPlasma®: Taking Industrial Surface Cleaning to the Next Level

Please download press release and images here

From October 7 to 9, 2025, Plasmatreat GmbH will present a pioneering solution for industrial surface cleaning at the parts2clean trade show in Stuttgart. This solution removes both stubborn organic and inorganic residues and will be showcased in Hall 10, Booth D52. The plasma specialist from Steinhagen, Germany has equipped its Plasma Treatment Unit (PTU) with the latest technology and will bring this system to Stuttgart. HydroPlasma® — a combination of Openair-Plasma® and distilled water — enables the efficient, environmentally friendly, and material-friendly preparation of substrates for demanding processes such as structural bonding, sealing, or coating.

In many manufacturing processes, such as those in the automotive industry and renewable energy production, achieving absolute surface cleanliness is crucial for ensuring high-quality, long-lasting results. Residues that can negatively affect subsequent processes, such as fingerprints or oil residues, must be reliably removed. HydroPlasma®, developed by Plasmatreat GmbH in Steinhagen, North Rhine-Westphalia, fills this gap by expanding the range of products with its new solution. This process effectively and environmentally friendly removes organic and inorganic residues from a variety of materials.

These basic tasks include ultra-fine cleaning, activation, reduction, and coatings for a wide range of industrial applications.

HydroPlasma®: Live Demo and Fluorescence Analysis

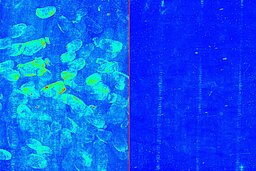

Visitors can look forward to unique live demonstrations of the new HydroPlasma® process at booth D52 in hall 10. The Plasma Treatment Unit (PTU) is equipped with Openair-Plasma® and HydroPlasma® technology. Metal parts contaminated with fingerprints or oil residues, such as release agents, will be cleaned and analyzed live. Fraunhofer IPM's fluorescence scanner will be used for analysis. The scanner's analysis will clearly show the difference in surface cleanliness before and after treatment by comparing images of the surface before and after cleaning. Visitors are also invited to bring their own flat material samples, which will be cleaned on-site and analyzed with the scanner.

The technology on display enables the highly effective, environmentally friendly cleaning of a wide variety of materials, from flat to complex or large-format components, and is particularly aimed at professionals in parts cleaning, quality assurance, and surface technology.

How HydroPlasma Works

HydroPlasma® combines the physical cleaning effect of Openair-Plasma® — also developed by Plasmatreat — with the chemical reactivity of water. When distilled water is fed into the plasma process, highly reactive oxygen and hydrogen radicals are created. These radicals dissolve residues on surfaces into water-soluble or gaseous components that can be easily removed. This environmentally friendly technology uses water, air, and electricity and does not require chemical solvents or emit VOCs. The water that is fed into the process cools the plasma jet that hits the surface, enabling the treatment of more temperature-sensitive materials.

A wide range of industrial applications

HydroPlasma is suitable for a variety of surface materials:

- Metal – Improved adhesion of coatings and seals: Aluminum housings for control units or sensors in the automotive and electronics industries require absolutely clean surfaces to ensure the long-lasting adhesion of protective coatings or sealants. HydroPlasma® reliably removes contaminants that impair adhesion or promote corrosion, such as oil residues, processing additives, and salts. The result is more stable bonds, less waste, and more durable components.

- Plastic – No thermal damage or deformation: Modern plastics used in medical technology or lightweight construction are often sensitive to heat. The cooling effect of the water used in the HydroPlasma® process makes it particularly suitable for plastics with low processing temperatures.

- Glass – Residue-free cleaning: Many vehicle and oven windows have a black edge ("blackout") created with ceramic screen printing. This protects the adhesive behind the window from UV light and improves its appearance. However, fingerprints left behind during this process can lead to loss of adhesion or leaks. HydroPlasma® offers an effective, environmentally friendly alternative to solvent-based cleaners.

"With HydroPlasma®, we offer the industry a powerful, eco-friendly, and cost-effective solution to one of the greatest challenges of modern manufacturing — the reliable, chemical-free cleaning of a wide variety of surfaces. This opens up new avenues for quality and sustainability in production," explains Magnus Buske, managing director at Plasmatreat GmbH. “But our technology is not only suitable for cleaning; it can also be used for coatings. Our PlasmaPlu® AntiCorr® application is specifically designed for metal applications, such as housing seals in the automotive industry. In this case, we apply an ultra-thin, silicon-like layer that reliably and sustainably protects components from crevice corrosion. This process is already in widespread use and meets the usual climate and salt spray tests, such as PV1209 or the MeKo-S test."