Improve manufacturing yield in Electronics with Openair-Plasma®

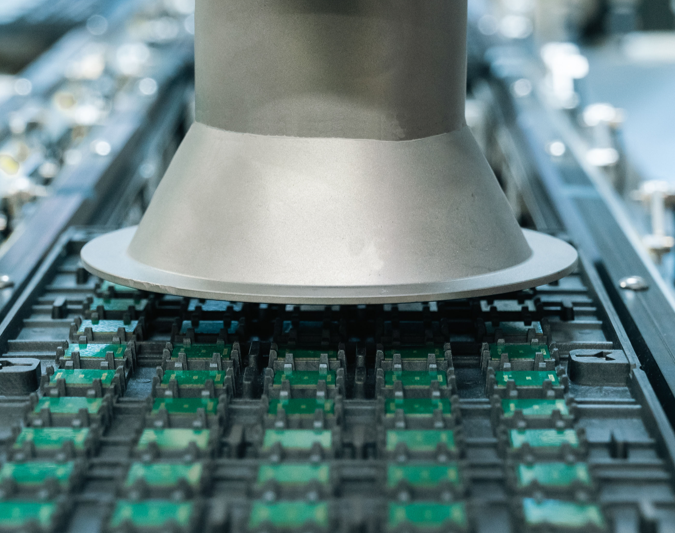

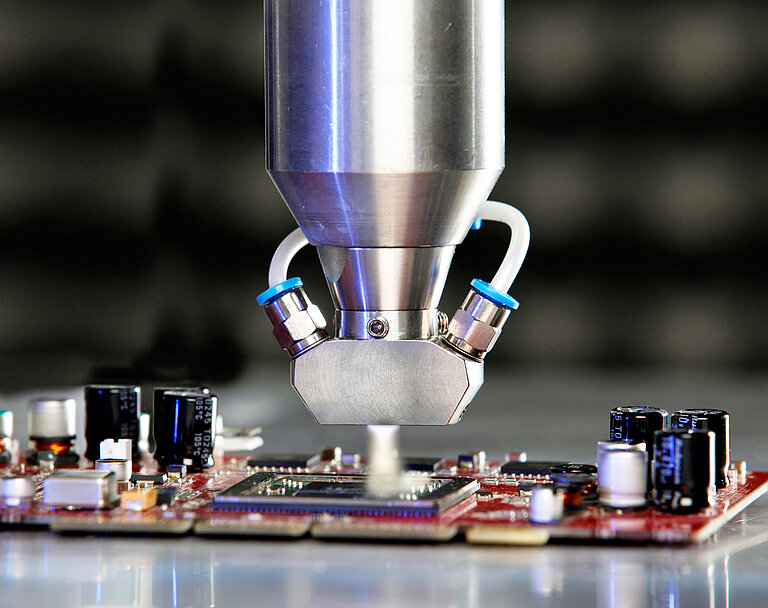

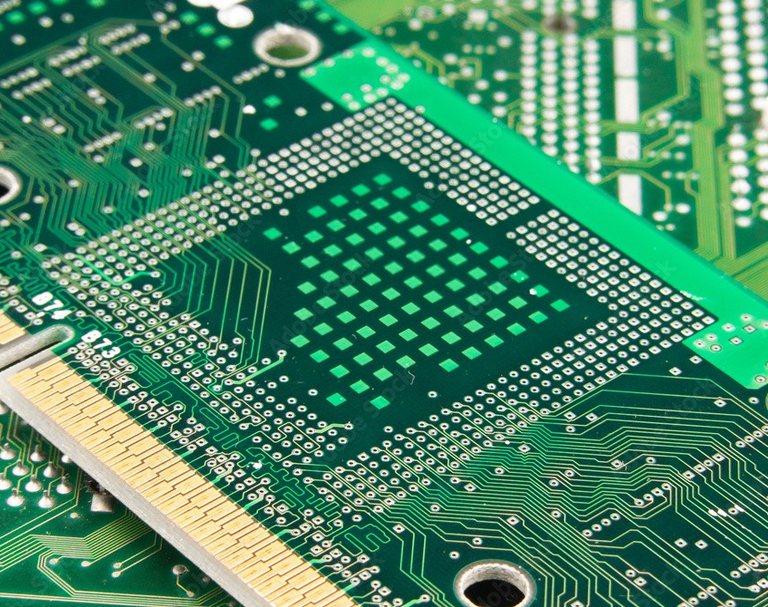

In electronics manufacturing, surface treatment plays a critical role in ensuring strong adhesion between dissimilar materials, improving coating wettability, and enhancing overall functionality. Openair-Plasma® provides an efficient, in-line, and selective dry surface treatment under atmospheric conditions — without the need for vacuum systems or chemical primers. This environmentally friendly and cost-effective technology supports a wide range of electronics applications, including semiconductor packaging, PCB assembly, electronic module assembly, and component manufacturing.

Benefits of Openair-Plasma® technology

- Selective application: Plasma can be switched on and off instantly — for precise, on-the-fly treatment.

- Ultra-fine cleaning: Effectively removes contaminants without damaging delicate or sensitive structures.

- Targeted surface functionalization: Enables localized surface activation for selective downstream processing.

- Environmentally friendly: No wet chemicals or solvents required — a completely dry and sustainable solution.

- Cost-effective: Operates using only oil-free compressed air; no expensive consumables needed.

- Fully in-line compatible: The plasma process is faster than conformal coating, so it doesn’t slow down production cycles.

Openair-Plasma® process

Openair-Plasma® is used to precisely modify surface properties in order to significantly improve the adhesion of materials — such as coatings, adhesives, or potting compounds — to substrates like PCBs. The plasma process reliably removes organic contaminants and silicone-based residues. At the same time, reactive oxygen species (e.g. hydroxyl and ketone groups) are incorporated into non-polar surfaces, resulting in chemical activation. This leads to a dramatic increase in surface energy — often exceeding 72 mN/m — and enables excellent wettability for subsequent processing.