等离子技术突破:航空航天领域粘接与防腐创新

技术演讲:更洁净、更牢固的粘接

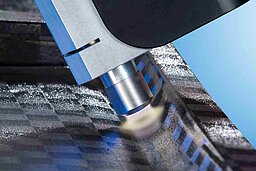

随着复合材料在航空航天设计与制造中的快速普及,行业日益依赖高强度、耐用且环保的粘接技术。题为《通过等离子改性提升复合与金属结构粘接强度及防腐性能》的演讲将重点阐述:大气压等离子射流通过提高表面自由能 (SFE) 和实现共价键合,从而增强粘接强度——且完全避免传统表面处理(如喷砂或化学蚀刻)造成的损伤、污染或环境危害。

Plasmatreat的Openair-Plasma® 技术在碳纤维复合材料上实现比未处理表面高出40%的搭接剪切强度,其性能优于溶剂擦拭、手工打磨甚至激光烧蚀等方法。

演讲还将展示等离子防腐屏障涂层的新研究成果。该技术作为纳米级连接层应用于金属基材,可有效阻隔粘接界面的湿气渗透——这是航空航天环境长期耐久性的关键因素。通过硫酸铜溶液测试,铝样件展现出卓越的耐腐蚀性能。

技术聚焦:航空航天级等离子系统

在CAMX 2025展会上,Plasmatreat还将展示其低压大容量等离子系统——专为航空航天领域最严苛的应用而打造。这些系统专为大型复合板材、夹层结构、蜂窝芯材及其他航空常用轻量化部件的预处理设计,适用于机舱内饰、机身总装及结构粘接等工艺。

Plasmatreat低压等离子系统兼顾研发与规模化生产需求,具备以下特性:

- 大型真空舱内实现高均匀性等离子处理

- 稳定可重复的表面活化效果

- 零有害废弃物产生,符合可持续发展倡议

我们的目标是让航空航天工程师获得更优质的粘接工艺——更清洁、更稳定,且符合行业自动化和可持续发展趋势,"Plasmatreat北美分公司总裁兼首席执行官Hardev Grewal表示。 “从用于在线预处理的大气压等离子射流,到处理全尺寸几何复杂部件的真空舱室,我们正在提供提升性能与可靠性的实用解决方案。”

欢迎莅临Plasmatreat D56展位—— 体验现场演示、技术讲座与表面处理咨询

Plasmatreat将在D56展位提供现场等离子演示、实时表面处理咨询及每日技术讲座。每日上午11:30,参观者可参加为期30分钟的技术交流会,聚焦等离子表面预处理、活化及工艺认证三大核心领域。现场将使用Brighton分析工具进行实操解析,并由Brighton Science技术专家提供实时数据解读与专业指导。

Plasmatreat还将在整个活动期间提供现场表面处理咨询服务。欢迎参观者携带自有材料样品,由我们的技术团队进行实时分析并提供个性化解决方案。这种实操式服务旨在帮助制造商直接在场内评估表面处理状态、提升附着力、减少返工并优化粘接工艺。

我们期待在D56展位欢迎您的到来,并向您展示等离子技术如何为您的产品提供保护 —— 同时守护我们的地球。