用于聚氨酯模内涂层的等离子处理技术

众多制造商倾向于采用常压等离子技术进行表面预处理,以增强塑料材质的附着力。在2025年K展上,常等离子技术领域的全球市场领导者Plasmatreat GmbH与拜罗伊特新材料研究院共同展示了一项创新应用:在施加聚氨酯涂层前,采用Openair-Plasma技术对注塑成型部件进行表面改性,以提升产品质量、减少次品率、简化工艺流程,并降低环境影响。与火焰处理等替代方案相比,等离子技术具备多重显著优势。

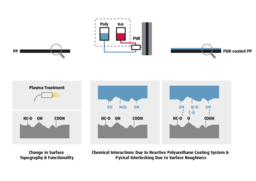

聚氨酯涂层系统已在汽车制造业外饰件(如引擎盖和前保险杠)的生产中广泛应用。这类涂层能保护塑料部件免受环境影响、吸收冲击力,并在受到机械损伤时展现出自修复特性。然而,为降低成本并提升可回收性,行业正转向使用聚丙烯等廉价单一材料制造部件,这一趋势带来了新的挑战。聚丙烯属于非极性材料,涂料难以在其表面实现良好且持久的附着。因此,聚丙烯必须进行预处理。传统的预处理方法,例如火焰处理或使用化学增粘剂,虽能提升附着强度,但也存在明显缺陷:包括可能损伤部件的高热量输入、需要额外的劳动安全与环保措施,以及因操作和干燥时间导致的工艺中断。作为替代方案的等离子技术,凭借其技术特性,能够从根本上消除这些弊端。

聚氨酯模内涂层——全自动、高速、在线工艺

这项由等离子行业技术专家Plasmatreat GmbH公司与拜罗伊特新材料研究院共同开发的新工艺,为未来高效、强效且环保的聚氨酯模内涂层技术展现了潜力。塑料部件在注塑成型后,随即通过特制的宽幅等离子喷枪进行处理。由机器人控制的的喷枪通过Openair-Plasma技术对塑料部件进行高速、精确的大面积预处理。随后,在同一套系统中为部件涂覆聚氨酯涂层。Plasmatreat开发了等离子控制单元以监控等离子处理过程。该控制单元通过集成的质量保证模块持续监控等离子工艺的所有参数,以确保其功能性与结果的可重现性。此制造工艺将注塑成型、等离子预处理和聚氨酯涂层整合为一条全自动在线流程,避免了额外的物流周转、清洁工序和等待时间。

等离子技术赋能高效的PUR涂层工艺:为工业领域开拓新前景

相较于其他表面处理方法,这项新型等离子技术具备多重优势。Openair-Plasma预处理技术能提升聚丙烯等非极性塑料的表面能,从而实现聚氨酯涂层的持久可靠附着。可靠的等离子工艺确保了处理结果的一致性及质量的可重现性,即使面对复杂几何形状的部件也不例外。与传统火焰处理工艺相比,等离子处理对部件的热负荷显著降低,避免了材料损伤。使用等离子技术还能减少塑料部件的材料厚度,从而节约成本。此外,该工艺具有高度灵活性。等离子预处理可进行大面积处理,也可实现区域选择性处理。宽幅等离子喷枪能快速适应高速生产节奏。另一项优势在于环保性:该过程无需化学溶剂,也不产生挥发性有机物排放。由于部件无需干燥时间或额外清洁步骤即可直接处理,聚氨酯模内涂层技术实现了短周期、高产量的生产目标。

“NMB与Plasmatreat的合作源于汽车行业的特定需求。我们的解决方案展示了如何将资源节约、效率提升与顶级产品质量相结合。通过将等离子技术引入PUR模内涂层工艺,我们正为汽车工业以及家电行业等其他领域,开辟全新的前景。”Plasmatreat GmbH的首席执行官Lukas Buske说道。