消費財の品質とサステナビリティ向上を実現

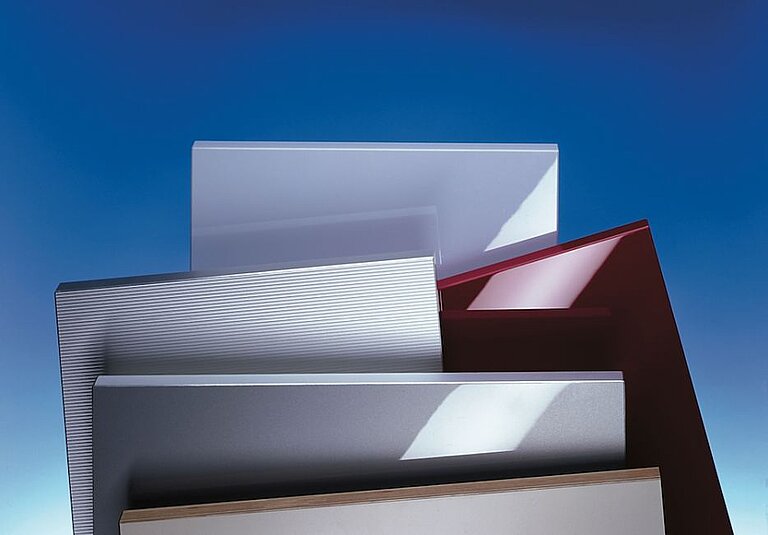

消費者が求める製品品質はさらに高度化しており、光沢面への高精度な印刷・コーティング、耐久性の高い接着、ボンドラインの見えない家具エッジ、環境に配慮した製造、新しい素材の組み合わせによる設計、防汚・撥水・非粘着・抗菌・難燃など多彩な機能を付与する表面処理など、要求はますます多様化しています。

大気圧プラズマ技術 Openair-Plasma®(オープンエアープラズマ) と 機能性コーティング技術 PlasmaPlus®(プラズマプラス) は、こうしたニーズに対応し、幅広い応用分野で活用できる先進的でコスト効率の高い表面処理ソリューションを提供します。

![[Translate to Japanese:] [Translate to Japanese:]](/fileadmin/_processed_/8/c/csm_AdobeStock_33842138_8544fe6200.jpeg)