界面品質が左右する半導体の信頼性

現代の半導体パッケージは、金属/金属、金属/ポリマー、さらにはさまざまなポリマー組み合わせから成る複雑な多材料システムで構成されています。

その信頼性は、材料界面がどれだけ清浄で、かつ長期にわたって安定した結合を保てるかに大きく依存します。

これらの界面にわずかな欠陥が生じるだけでも、層間剝離、クラック、または予期せぬ故障を引き起こす可能性があります。

この重要な界面品質を損なう主な要因は次のとおりです。

- 酸化膜の形成:不要な領域に形成された酸化膜は、適切な接着や電気的接触を妨げます。

- 濡れ性の不足:表面の濡れ性が不十分な場合、接合プロセス中の均一な密着や材料の安定した流動が阻害されます。

- パーティクルや残渣による汚染:微粒子や有機残渣の付着は、接合部の欠陥や早期故障を引き起こします。

- 熱膨張係数の差 (CTEミスマッチ):温度変化に伴う機械的応力や微細亀裂の発生により、界面の長期信頼性が低下します。

これらの課題はすべて、有害な薬品や高コストな真空装置、特殊ガスを用いることなく、プラズマ技術によって効果的に解決できます。

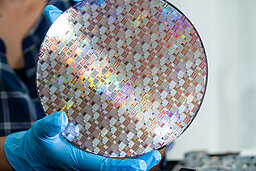

Openair-Plasma®技術の登場により、ウェーハ洗浄プロセスは大きく進化しました。

現在では、大気圧プラズマが真空を必要とせず、生産を止めることなく、ナノレベルの表面洗浄をインラインで実現します。真空工程を省くことで、Openair-Plasma®はプロセスの簡素化と自動化の促進を同時に達成します。ウェーハはスライシングや研磨の工程から直接プラズマ処理に移行でき、有機残渣や微粒子を効果的に除去します。その結果、エラーの減少、生産スピードの向上、プロセス効率の最適化が実現します。

この真空を伴わないインライン型プラズマプロセスは、あらゆる半導体材料において最高レベルの表面清浄度を保証します。化学薬品を一切使用せず、生産ラインを停止させることなく、高い信頼性と再現性を備えた洗浄プロセスを提供します。また、この技術は自動化製造ラインへの統合が容易であり、生産コストの削減と環境負荷の低減の両立に貢献します。

その結果、すべてのウェーハがワイヤボンディングやダイアタッチなどの次工程に最適な状態でパッケージングプロセスに進み、製造初期段階から高いデバイス信頼性を確保します。

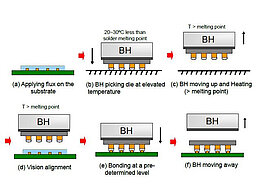

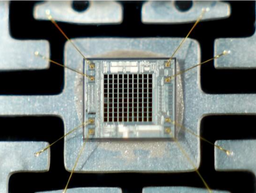

ダイボンディング — ダイアタッチ工程でプラズマ処理が欠かせない理由

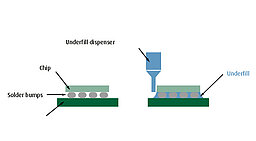

ダイアタッチプロセスの品質は、あらゆる半導体デバイスの信頼性と性能を左右します。接合の不均一やボイド、不十分なダイの密着は、デバイスの使用開始から製品寿命に至るまで、機能に悪影響を及ぼすおそれがあります。

Openair-Plasma®によるプラズマ前処理は、すべてのダイと基板の表面を最適な状態に整えることで、安定したダイアタッチ工程を実現します。有機残渣や酸化膜をインラインプロセスで効果的に除去し、真空装置や強力な化学薬品を使用せずに表面を高精度に活性化します。

プラズマ処理の有無による違いは明確です。処理を行わない場合はボイドやデラミネーション (層間剥離)、密着不良が発生しやすくなりますが、プラズマ処理を施すことで、すべてのダイが安定して強固かつクリーンに接合されます。

主な効果として、プロセス信頼性と接合品質の向上、酸化膜除去による表面清浄度の改善、および接着剤・エポキシ・はんだへの高い密着性があげられます。優れた濡れ性によりボイドや剥離を低減し、熱的・機械的ストレス下でも安定したデバイス性能を維持します。その結果、歩留まりの向上、工程ロスの低減、製品品質の一貫性が実現します。

つまり、Openair-Plasma®の導入により、ダイアタッチ工程の各ステップが高精度で安定した前処理プロセスへと進化し、あらゆる条件下でも高い信頼性と長期安定性を備えた半導体デバイスの製造が可能になります。

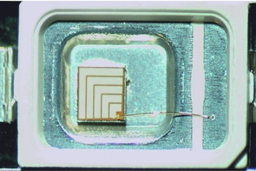

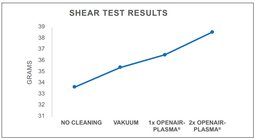

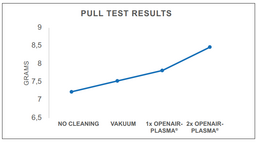

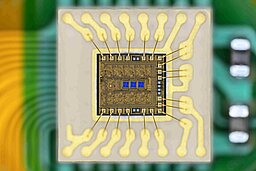

高品質なワイヤボンディング接続は、あらゆる最新ICの信頼性を支える基盤であり、その品質は、清浄で活性化された表面状態によって決まります。 酸化膜や有機残渣など、わずかな汚染物でも「ノンスティック・オン・パッド (NSOP)」、せん断強度の低下、さらには早期故障の原因となります。

プラズマ活性化処理は、これらの課題を根本から解消する有効な手段です。 汚染物を効果的に除去し、ボンドパッド表面を最適な状態に活性化することで、強固なワイヤ接合と高い電気的・機械的安定性を確保します。 その結果、弱い接合やボンドリフト、コストのかかる再加工の発生を大幅に低減し、歩留まりの向上、安定した再現性、そしてパッケージング工程全体における高い品質信頼性を実現します。

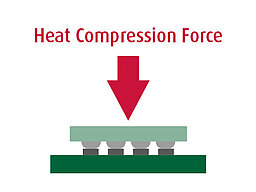

モールディング・封止工程における表面前処理

信頼性の高いモールディングおよび保護封止を実現するためには、基板表面の品質が極めて重要です。リードフレームや微細ワイヤから高機能封止材に至るまで、関係するすべての材料は、汚染や酸化がなく、化学的に高い反応性を備えている必要があります。この条件が満たされて初めて、材料の均一な流動性、優れた密着性、長期安定性が確保されます。

Openair-Plasma®は、これを実現するための専用プロセスを提供します。プラズマ洗浄は、密着性を損なう原因となる有機・無機残渣を除去し、剥離を防止します。プラズマ還元処理により、微細な金属酸化膜までも除去し、化学的に結合しやすい高活性な表面を形成します。さらに、PlasmaPlus®(プラズマプラス) ナノコーティングは、湿気から保護しつつ材料間の適合性を高める、薄く均一なバリア層を形成します。

これらのプロセスを組み合わせることで、封止材の最適な流動性を確保し、エアポケット (気泡) の発生を防止します。また、REACHおよびMSL1規格への完全準拠を可能にし、最も過酷な製造・稼働条件下でも高い信頼性を確保します。

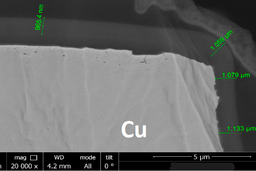

バリアコーティング — 高感度ICを原子レベルで保護

PlasmaPlus®に代表されるバリアコーティングは、高感度な半導体部品を湿気やイオンマイグレーション、さまざまな環境要因から確実に保護します。大気圧下で成膜される超薄膜 (通常700~1,000nm) の保護層が、内部部品の周囲に効果的なシールドを形成します。

この高機能コーティング技術は、水分やイオン汚染から部品を確実に保護し、電気的絶縁性と長期安定性を維持します。さらに、熱的・機械的ストレス下でも高い耐久性を発揮し、ICパッケージの信頼性を長期にわたり確保します。その結果、ICパッケージは過酷な環境条件下においても、機能性と電気的安定性を維持します。

最終組立工程における洗浄・マーキング

最終組立工程におけるOpenair-Plasma®技術の特長は、製品が出荷されるまで粒子や残渣を一切残さず、最高水準の清浄度と精度を維持できる点にあります。

さらに、あらゆる表面に確実で恒久的なマーキングを施すことで、トレーサビリティと耐久性を確保します。廃棄や不良を最小限に抑えることで歩留まりを最大化し、生産効率とコストパフォーマンスを両立します。

生産全体を通じてプロセスの信頼性と包括的な品質保証が維持され、最終工程に至るまで一貫した品質管理が行われます。清浄で最適に処理された最終製品こそが、安定した生産と長期的な信頼性の基盤となります。

これにより、常に高品質を一貫して提供し、顧客の期待を超える製品づくりを実現します。